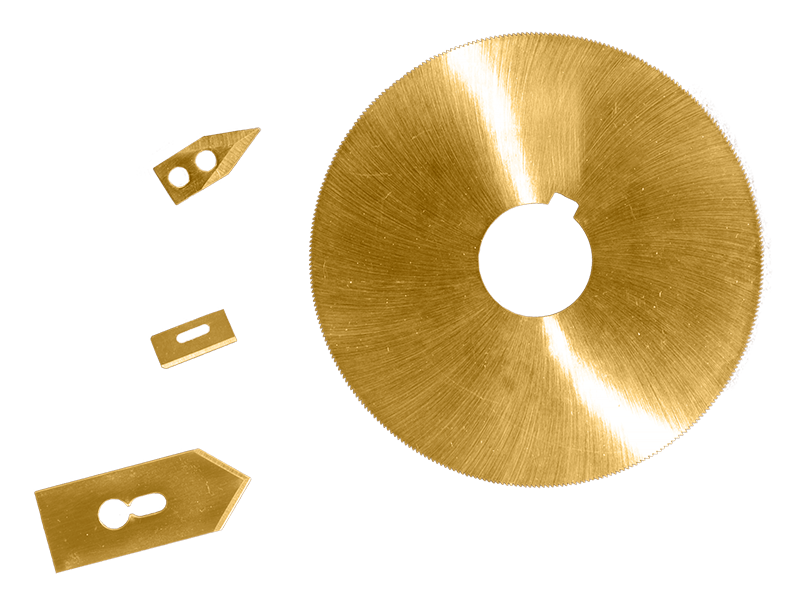

Titanium Nitride (PVD)

Strong, Hard and Wear-resistant Coatings for Sharp-edged and Tight-tolerance Parts

Titanium nitride surface treatments leverage physical vapor deposition (PVD) technology to improve surface hardness, prevent wear and reduce friction for sliding surfaces. They’re also ideal for protecting parts that have sharp edges or must be applied to tight geometrical tolerances.

PVD is a complex process. Titanium is evaporated by a high-energy source within a vacuum, and the resulting vapor reacts with nitrogen to create a strong, thin and durable film on a substrate.

We can engineer titanium nitride surface treatments that:

- Provide greater wear and abrasion resistance than stainless steel.

- Maintain sharpness for knife edges and cutting tools longer than other coatings.

- Add a rich, gold color to metals without distortion.

With our titanium nitride expertise and PVD capabilities, you have many possibilities.

Advantages

Better wear and abrasion resistance than stainless steel

Exceeds physical properties of common industry coatings

Prevents dulled edges and blade changes on cutting surfaces

Uniform application thicknesses to micro-inches

Long lifetimes

USDA and FDA compliance

Ideal Surface Treatments

Explore the Possibilities of Titanium Nitride PVD Coatings

If you require a surface treatment that’s a cut above common coatings, our experts are available to help you review your options.

Request a quoteTechnical Resources

Videos

Webinars

White Papers

Engineered Coatings Boost Throughput, Solve Problems in Packaging Applications

Keeping packaging equipment up and running is top priority for engineers and plant personnel. Faced with ever-increasing productivity benchmarks based on fast and efficient operation, packaging engineers must continually fight against issues such as sticking, premature wear, abrasion and corrosion. To eliminate these challenges, nano-engineered coatings are being used to protect machine components and solve performance problems in food, pharmaceutical and consumer goods packaging.

Case Studies

High-Tech, Space-Age Metal Surface Enhancement Coating Solves Wear and Release Problems for Pine Instrument Company's Gyratory Compaction Asphalt Testers

The development of computer-controlled asphalt testing equipment to simulate and then quantify and predict the punishment which various asphalt mixes will be able to endure when used to pave actual roads has placed enormous burdens on the components of that test equipment. To stand up to simulations of heavy road wear, equipment designers have had to look beyond the conventional and to seek out materials that could endure tremendous stress. That was precisely the position in which the worldwide, leading supplier of such equipment, Pine Instrument Company of Grove City, Pennsylvania, found itself.

Blog Posts

How Nedox® Keeps Oil and Gas Wireline Equipment Free From Wear and Corrosion

Nedox® surface treatments keep wireline housings and connectors in the oil and gas industry well-protected in punishing environments.