Non-stick Release Coatings

Surface Treatments With Non-stick Properties Eliminate Costly Production Downtime

Our coatings ensure and maintain productivity for a wide range of equipment subject to sticking and release issues. We offer FDA- and USDA-compliant coatings that prevent sticky food substances from slowing down machinery and affecting product quality. We also create coatings that prevent glue residue buildup and plastic mold adhesion that can damage equipment and cause cleanup delays.

We formulate surface treatments that impart performance attributes tailored to your application needs, such as non-stick/release properties and lower friction. The coatings create dense, non-porous and dry-lubricated surfaces that release substances better so equipment performs reliably. That means greater uptime and productivity, along with quality coated components.

Break Free From Sticking Issues

Ready to boost the release properties of your part surfaces? Our engineers are available to help you select the right coating for your application.

Request a QuoteIdeal Surface Treatments

Lectrofluor®

Polymer-based coating prevents severe corrosion and chemical attack to metals in hostile environments.

Capabilities

- Excellent mold release properties

- Prevents abrasive wear and galling

- Permanent self-lubricating properties for extended wear protection

- Excellent dry lubricity for low COF

- USDA and FDA compliance

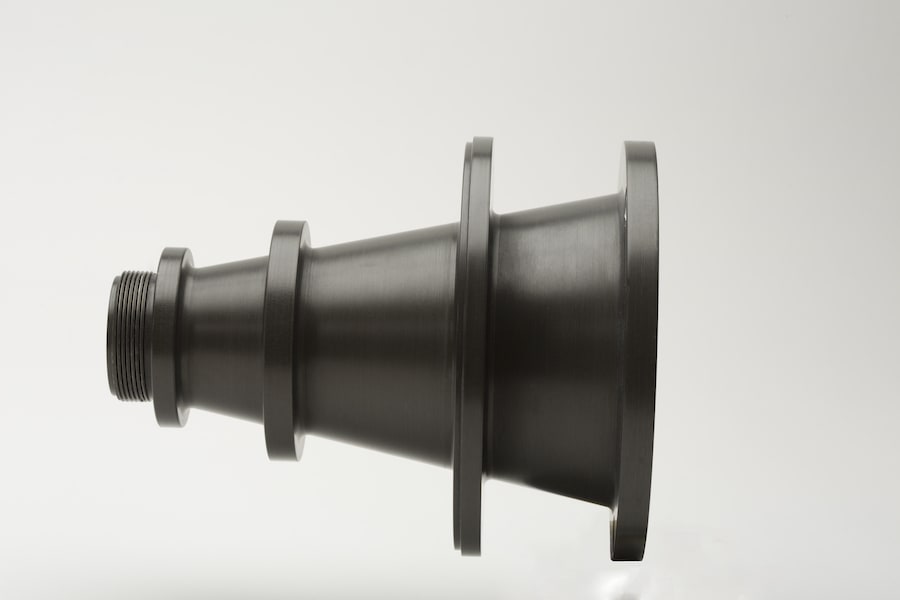

Nedox®

Electroless nickel coating known for its ability to eliminate stick-slip and galling in a wide variety of applications.

Capabilities

- Superior protection against wear, friction and corrosion

- Enables easy cleanup

- Self-lubricating, non-porous, non-wetting surface characteristics

- Chemical, acid and alkaline resistance

- Surface hardnesses up to Rc 68

- USDA and FDA compliance

Plasmadize®

This thermal spray composite protects and restores metal parts.

Capabilities

- Higher lubricity and better mold release than conventional thermal sprays

- Provides corrosion and wear resistance for all metals

- Hardnesses beyond the Rc scale

- Creates a non-porous, moisture-proof surface

- USDA and FDA compliance

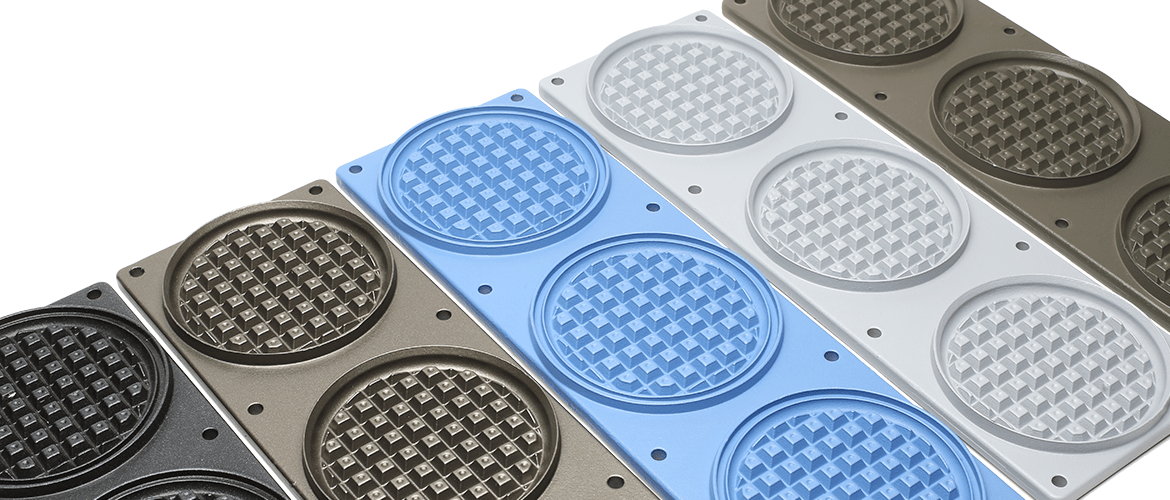

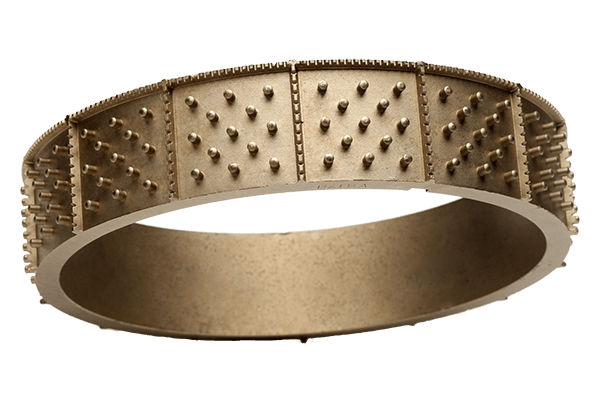

Tufram®

Hard anodizing coating protects aluminum and aluminum surfaces from corrosion and friction.

Capabilities

- Dramatically improves the surface hardness of aluminum

- Surface hardness between Rc 42 and Rc 50

- Self-lubricating and non-wetting surface characteristics

- Low COF to resist corrosion, abrasion and galling

- USDA and FDA compliance

Industries

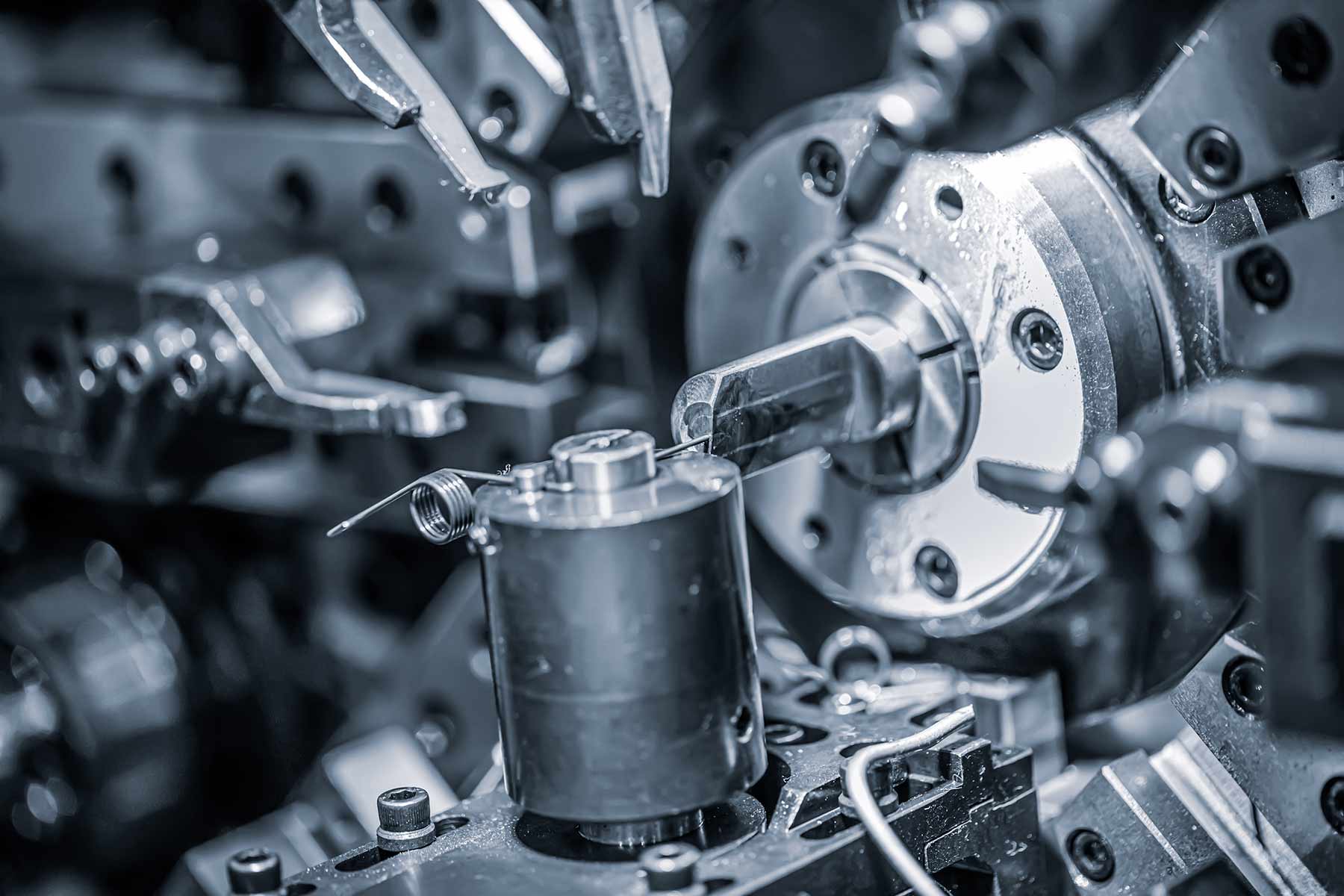

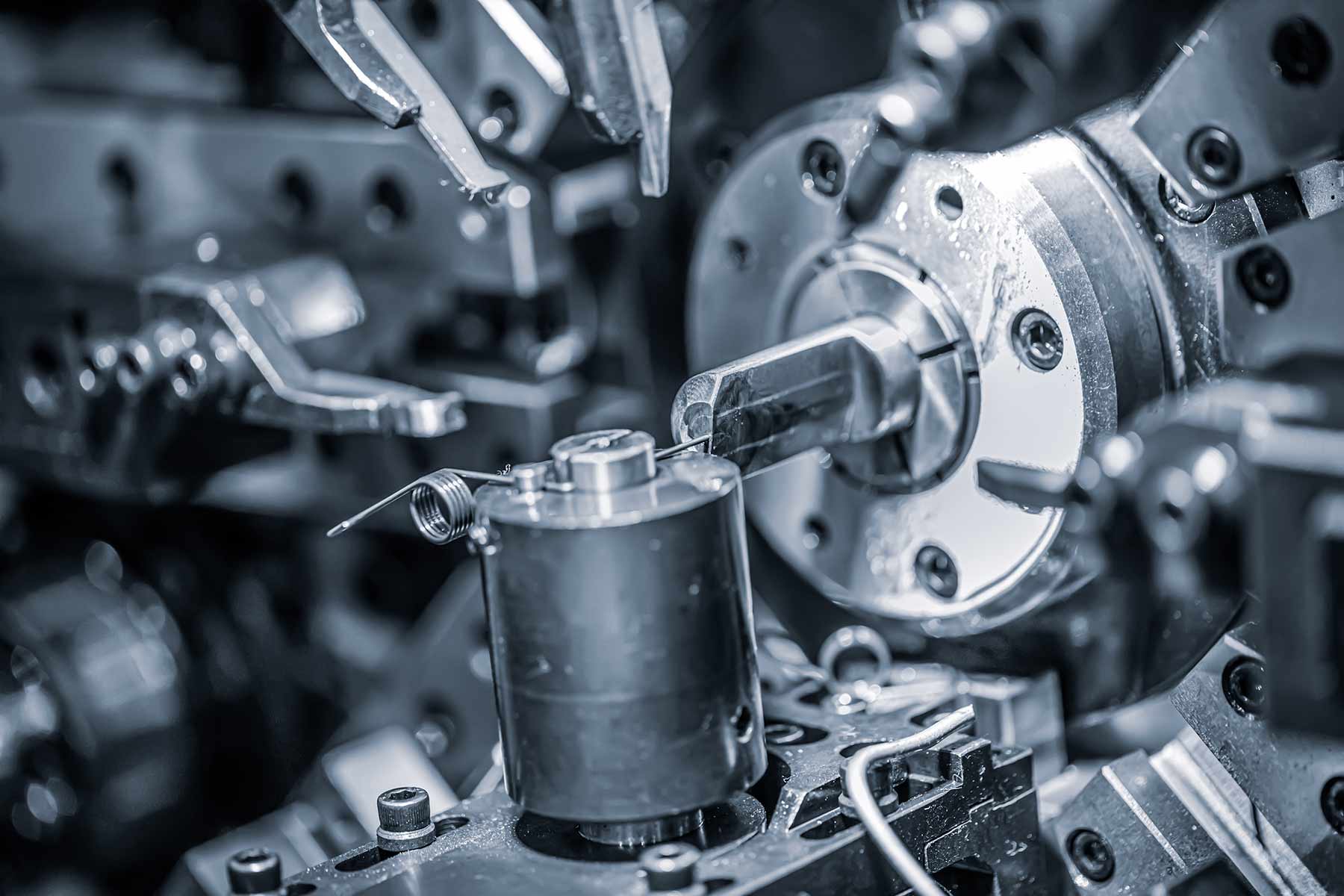

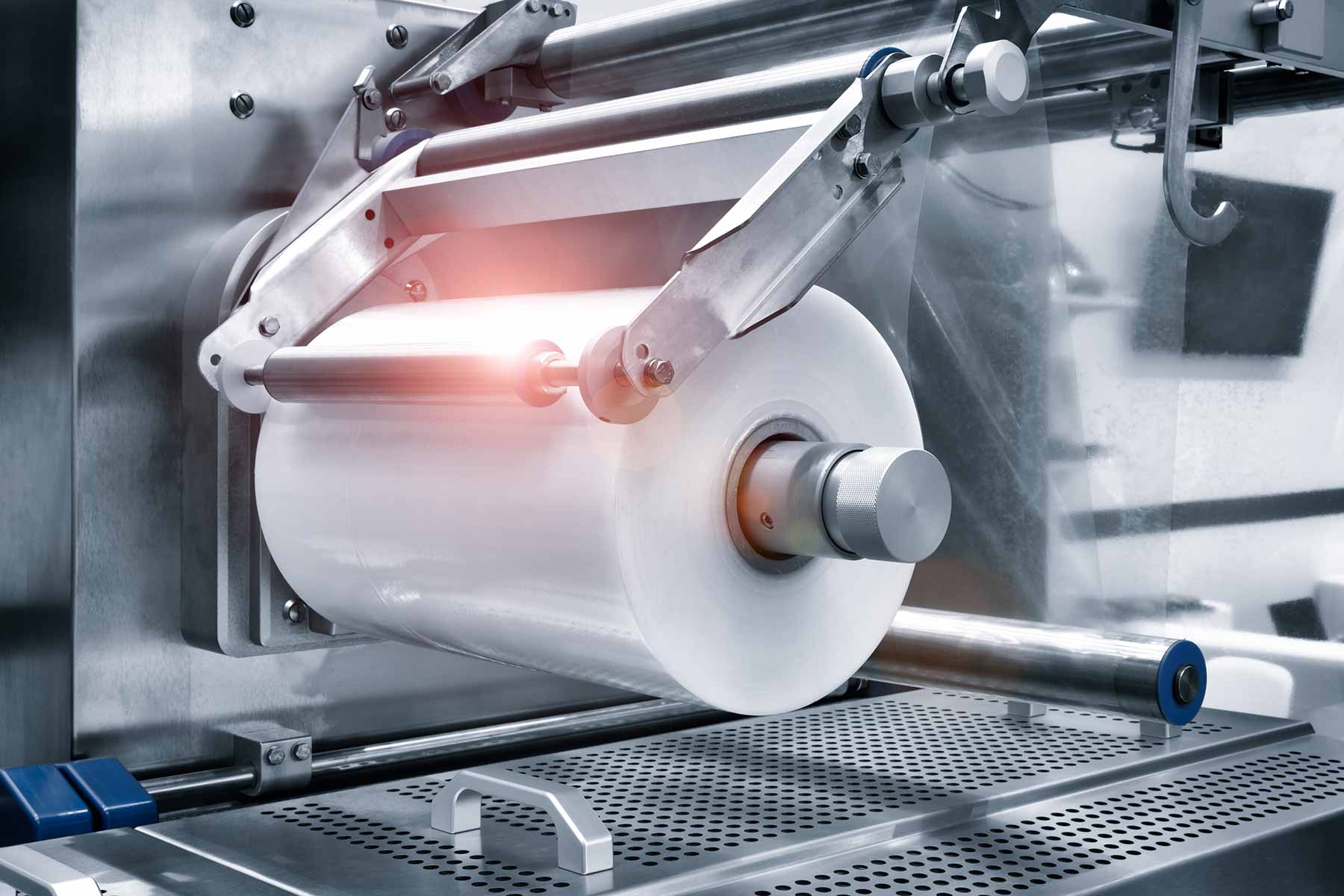

Manufacturing and Automation

Surface treatments keep high-speed manufacturing and automated processes moving without issues related to sticky substances and release. Tufram, for example, provides superior mold release and eliminates sticking and product hang-up. Plasmadize is a desirable coating for preventing adhesive buildup during the last step in manufacturing — packaging.