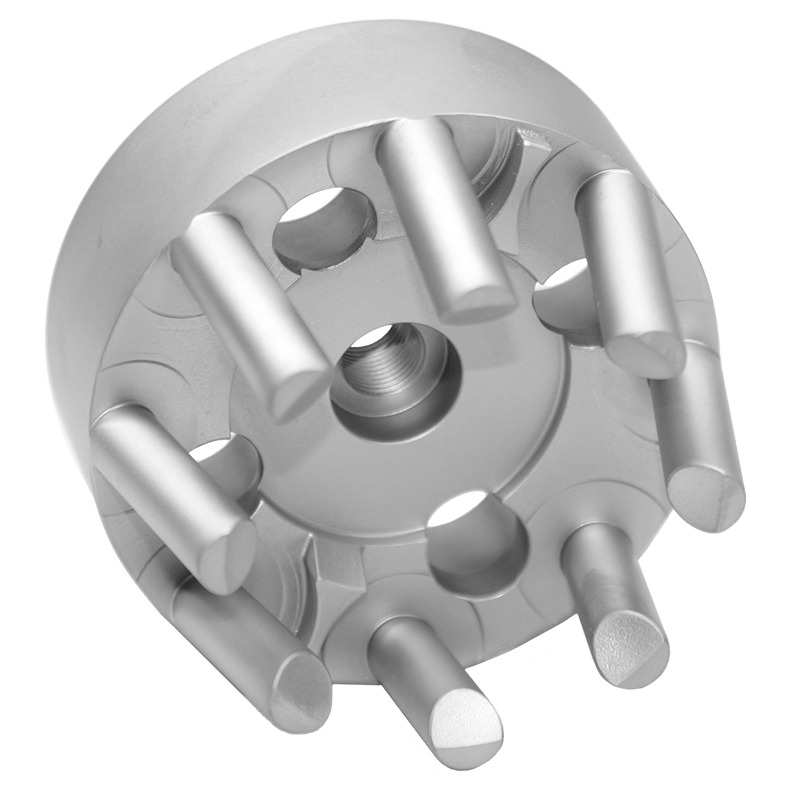

Thin Dense Chrome

Ultra-thin Chrome Coating for Wear Protection and Dimensional Precision

Thin, dense uniform coatings adhere precisely to tight dimensions without edge build-up, ensuring consistently high quality application every time. Developed to adhere to most ferrous base metals, our distinct coatings offer excellent protection against wear, galling, friction and corrosion.

Thin dense chrome coatings create a microfinish that helps disperse lubricants as well as eliminate friction on sliding surfaces. They reproduce, with precise detail, the surface morphology of the original metallic substrate, and they improve a base metal’s surface hardness and porosity to eliminate micro-cracks that otherwise promote corrosion. Thanks to the microfinish, there is no edge build-up. That means there’s no need for costly grinding and machining. And, their low processing temperatures allow parts to be processed at any point in their service life without affecting the substrate’s properties.

Advantages

Precise reproduction of substrate surface morphologies

Compatibility with most ferrous metals

Resists most organic and inorganic compounds

Minimal thermal distortion

When Accuracy and Reliability Count

Our technical experts are ready to help you select a dimensionally compliant, thin and dense chrome coating to solve your wear, friction and corrosion issues.

Request a QuoteTechnical Resources

Videos

Webinars

White Papers

Engineered Coatings Boost Throughput, Solve Problems in Packaging Applications

Keeping packaging equipment up and running is top priority for engineers and plant personnel. Faced with ever-increasing productivity benchmarks based on fast and efficient operation, packaging engineers must continually fight against issues such as sticking, premature wear, abrasion and corrosion. To eliminate these challenges, nano-engineered coatings are being used to protect machine components and solve performance problems in food, pharmaceutical and consumer goods packaging.

Case Studies

High-Tech, Space-Age Metal Surface Enhancement Coating Solves Wear and Release Problems for Pine Instrument Company's Gyratory Compaction Asphalt Testers

The development of computer-controlled asphalt testing equipment to simulate and then quantify and predict the punishment which various asphalt mixes will be able to endure when used to pave actual roads has placed enormous burdens on the components of that test equipment. To stand up to simulations of heavy road wear, equipment designers have had to look beyond the conventional and to seek out materials that could endure tremendous stress. That was precisely the position in which the worldwide, leading supplier of such equipment, Pine Instrument Company of Grove City, Pennsylvania, found itself.

Blog Posts

Plasmadize® Adds Life to Metal Impellers in Cardboard Recycling

When abrasive contaminants are present in recycling streams, Plasmadize® can rejuvenate metal parts and productivity.