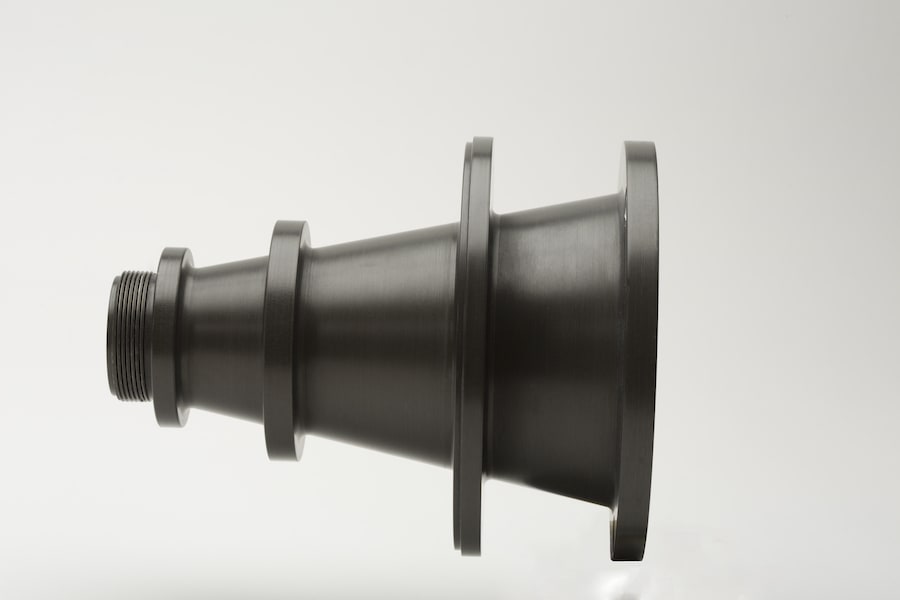

Corrosion and Chemical Resistant Coatings

Engineered Coatings Provide Potent Protection Versus Two Severe Causes of Downtime

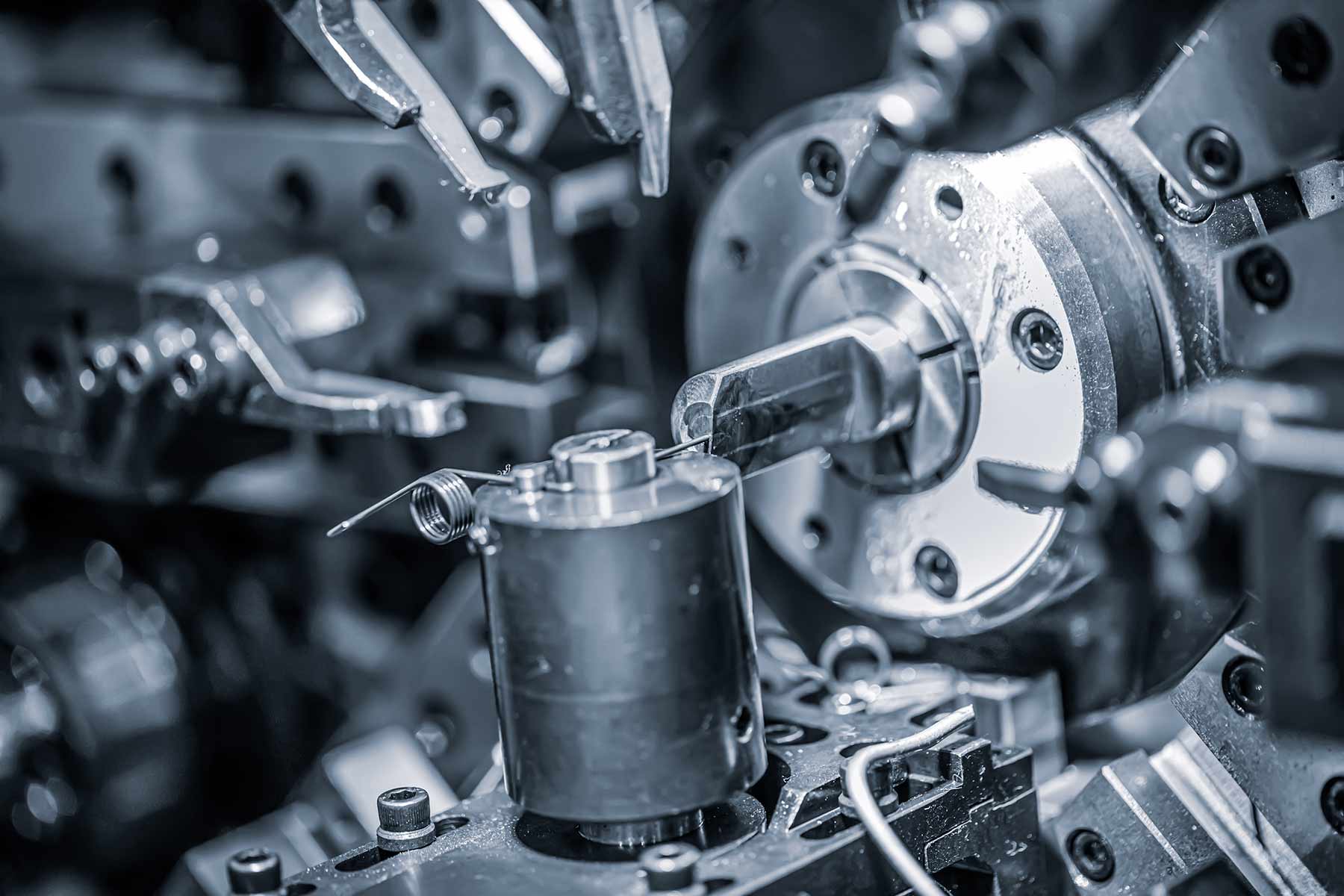

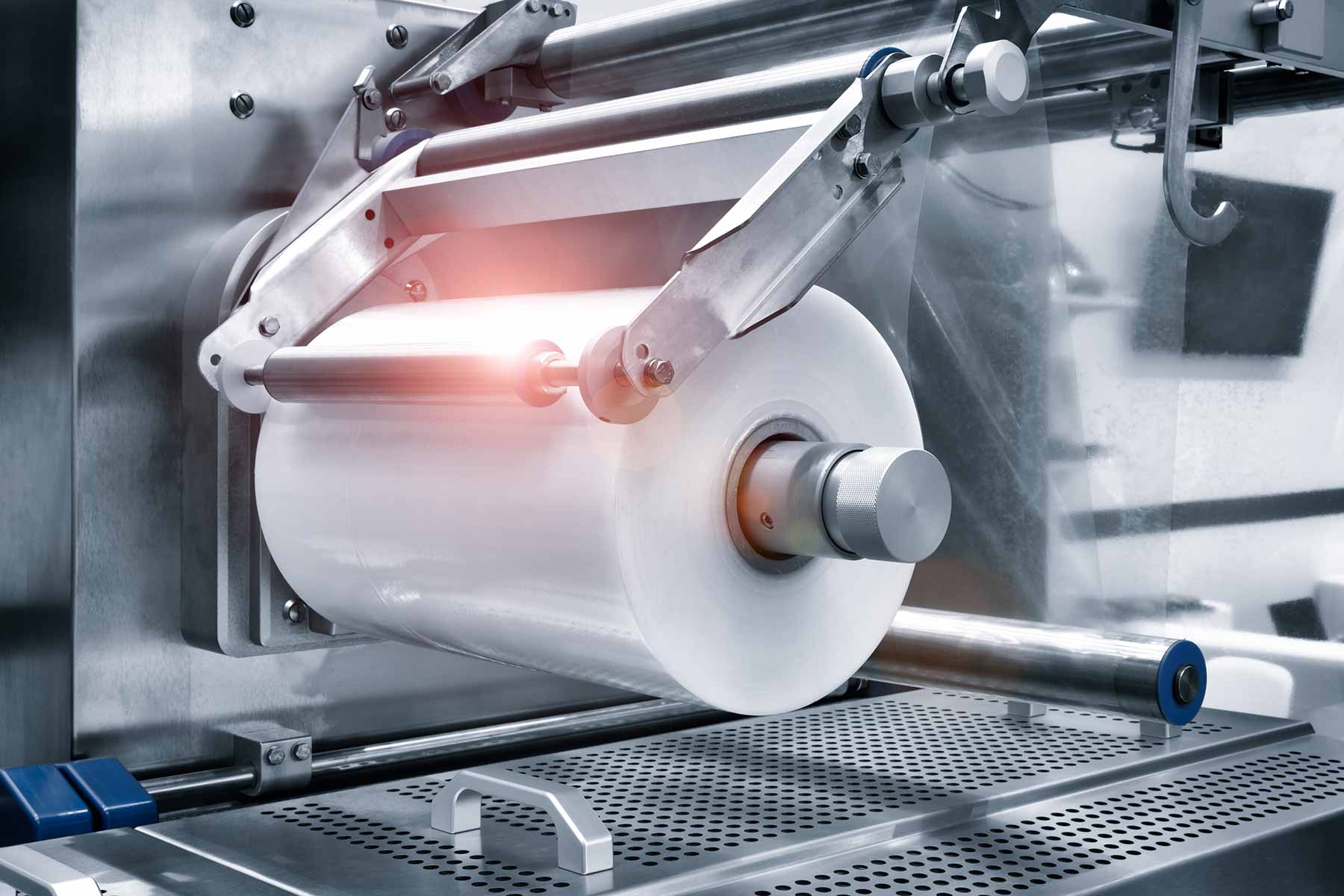

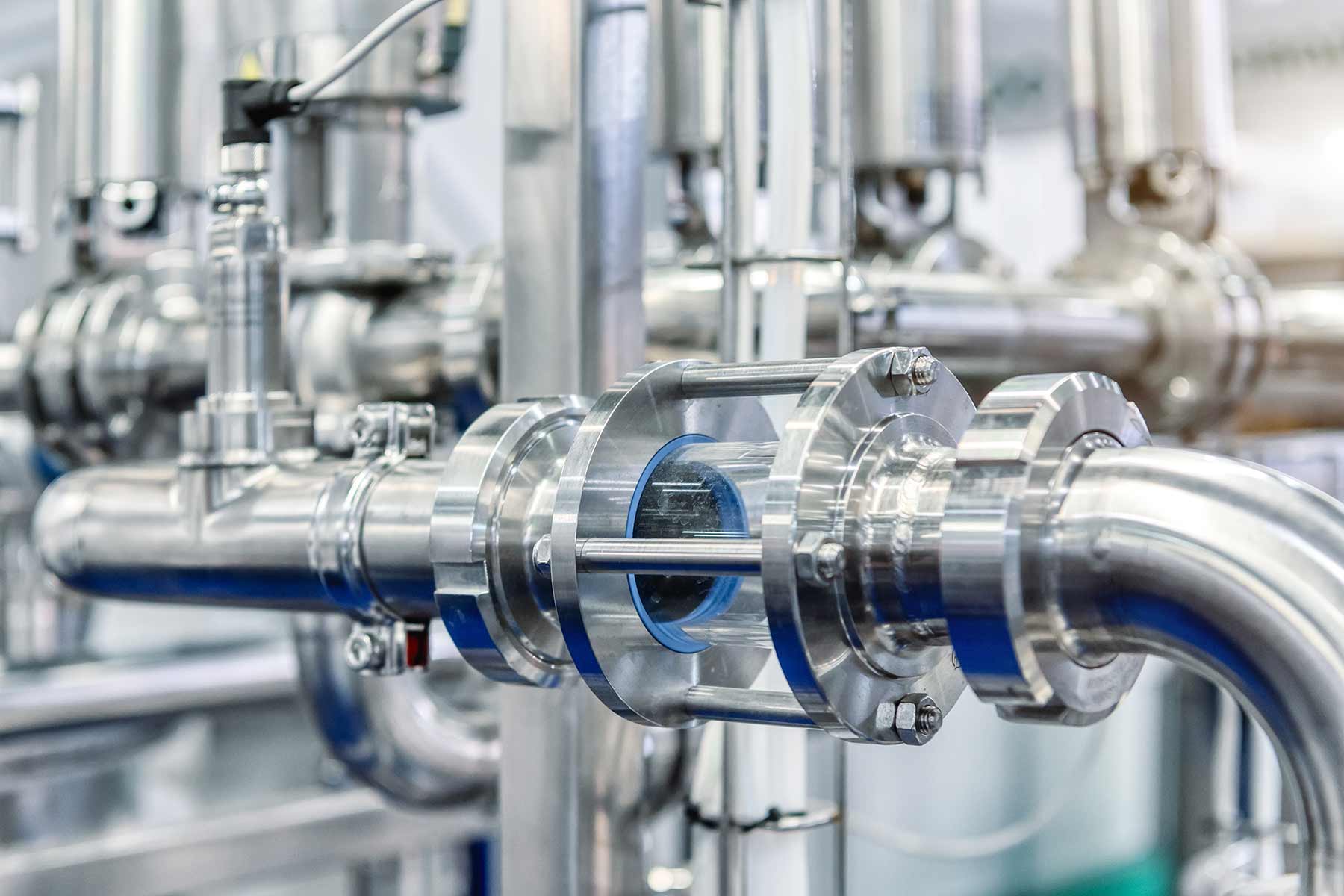

Corrosion and chemical attack are two of the most common causes of unplanned equipment downtime, and damage can come from a diversity of sources such as fluids, cleaning agents and saltwater. Our coatings effectively combat these threats by creating a nonporous protective surface on metal substrates, reducing the need to replace metal parts while extending their lifetimes.

Because corrosion and chemicals cause damage in many ways, we engineer our coatings for specific application factors that require action in order to give surfaces the attributes necessary to withstand these harsh conditions. That means your equipment will perform longer to help keep operating costs low.

Stop Corrosion and Chemical Attack

Our engineers are available to help you hold the line against corrosion and chemicals with the right coating for your application.

Contact UsIdeal Surface Treatments

Lectrofluor®

Dry-lubricity, polymer-based coating with superior chemical and corrosion resistance.

Capabilities

- Prevents severe corrosion and chemical attack to metals in hostile environments

- Broad resistance to chemicals, acids and alkalis

- Prevents galling

- Self-lubricating for extended wear prevention

- USDA/FDA/ITAR/ROHS code compliance

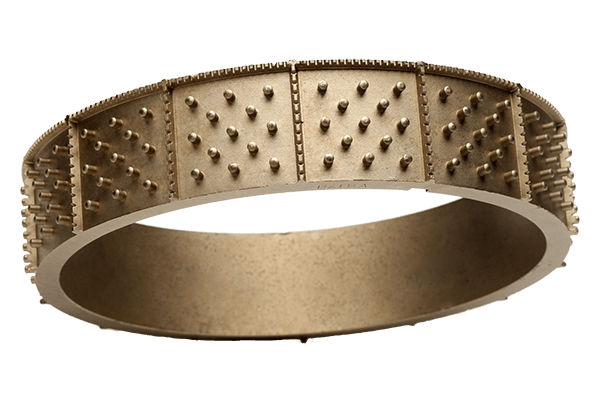

Nedox®

Electroless nickel coating provides superior protection against wear, friction and corrosion.

Capabilities

- Chemical, acid and alkaline resistance

- Prevents galvanic corrosion with incompatible metals

- Surface hardnesses up to Rc 68 (940 Vickers)

- Coating thicknesses between 0.0003 to 0.002 inch

- Self-lubricating, non-porous, non-wetting surface characteristics

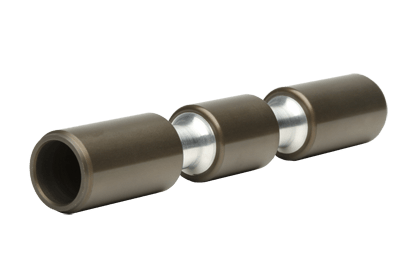

Plasmadize®

Thermal spray composite protects and restores metal parts.

Capabilities

- Provides corrosion and wear resistance for all metals

- Resists acids, alkalis, most organic solvents, chlorides, sulfites, thiosulfates and pulp bleaching chemicals

- Resistance in salt spray testing from 300 to 4,000 hours, depending on the polymer used and substrate

- Seals surface voids to eliminate porosity

- Hardnesses beyond the Rc scale

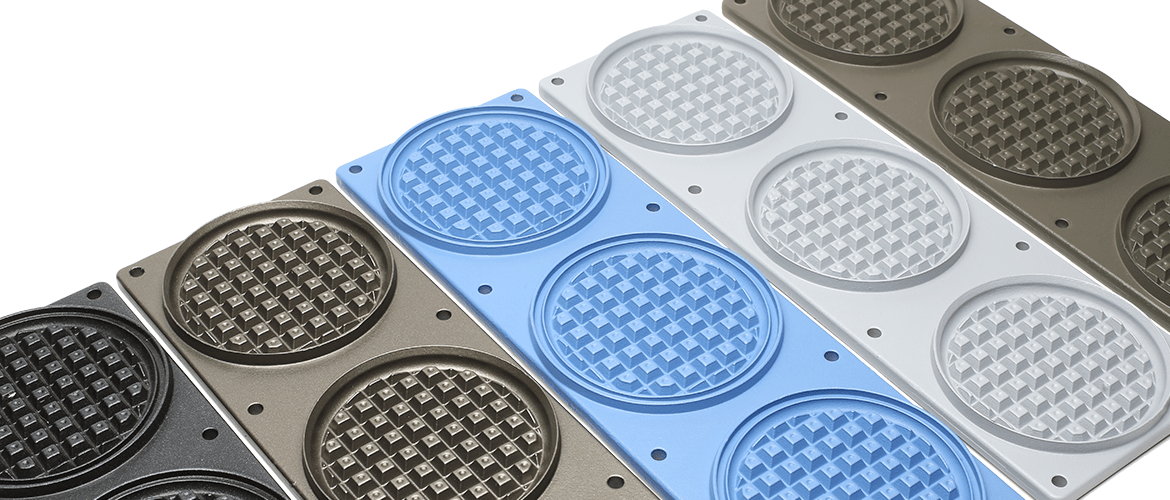

Tufram®

Hard anodizing coating protects aluminum and aluminum surfaces from corrosion and friction.

Capabilities

- Resistance to corrosion, abrasion and galling

- Dramatically improves the surface hardness of aluminum

- Exceeds the AMS 2482 salt spray requirement of 336 hours on high-strength aluminum

- Surface hardness between Rc 42 and Rc 50

- Self-lubricating and non-wetting surface characteristics

Industries

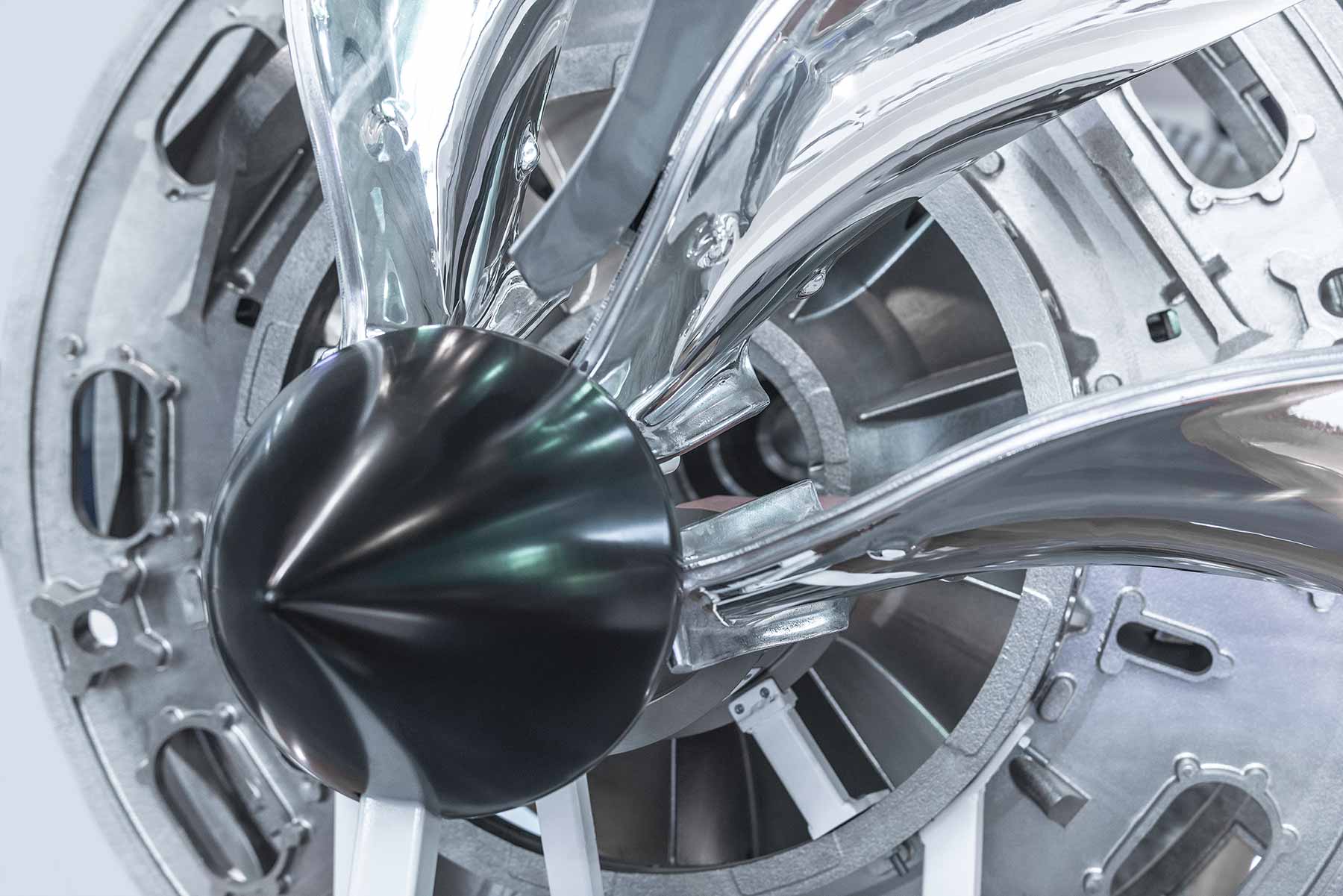

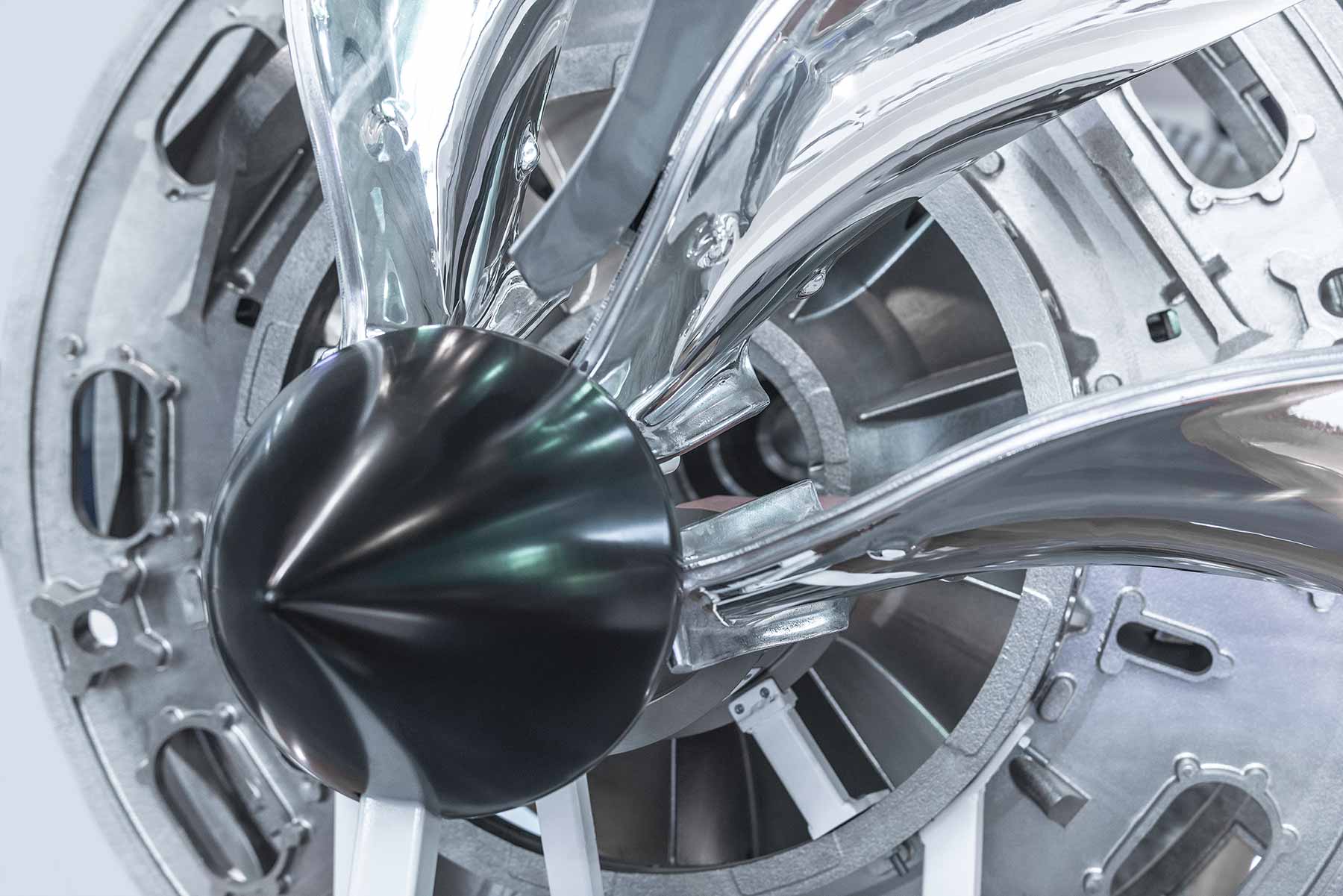

Aerospace and Defense

Aerospace and military parts are among the most expensive to produce and maintain, and they can be difficult or impossible to repair or replace in their intended applications. That makes surface treatments a critical line of defense against corrosive weather conditions and chemicals used during operations. Dynaloy is one of several Magnaplate coatings that withstand extreme temperatures, with operation up to 1,699°F. Tufram is well-suited for vacuum environments and has been applied to parts on many space vehicles.