USDA/FDA Coatings

Fight Threats and Improve Sanitation for Food, Pharmaceutical and Medical Equipment

When you need to protect food and pharmaceutical processing equipment against the effects of contamination, corrosion, wear and other threats, we have you covered with a variety of FDA- and USDA-compliant surface treatments.

Many of our coating families meet these strict regulations, allowing their use on parts that make direct contact with food, or undergo rigorous sterilization and wash-down procedures. Thanks to these coatings, you can meet critical objectives such as:

- Resistance to cleaning and disinfection, including harsh chemicals

- Easy sanitary cleanup

- High-temperature resistance up to 1000°F

- Release of sticky substances

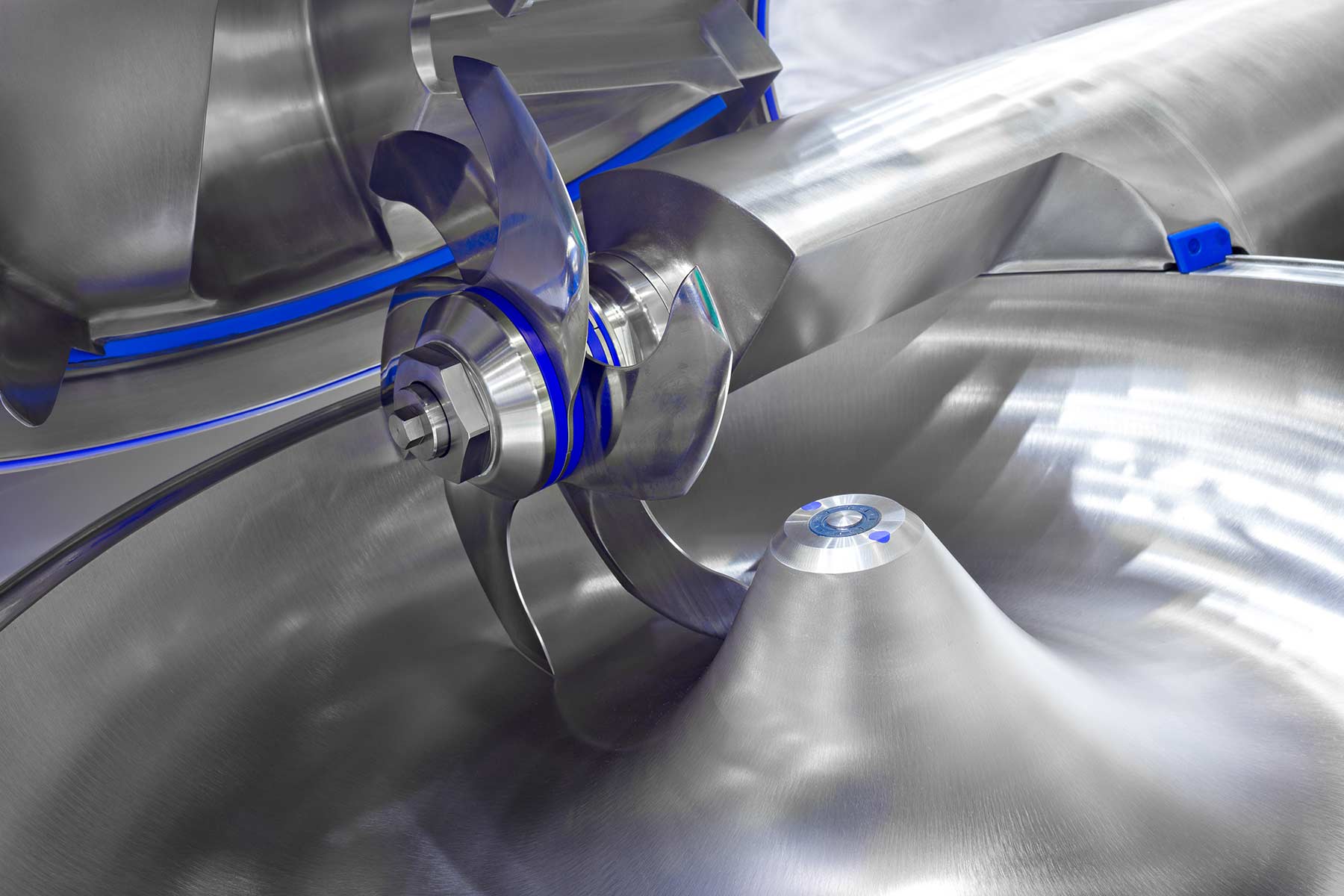

We can apply our FDA- and USDA-compliant surface treatments to a wide range of machinery, such as extrusion, forming, cutting, cooking, filling, feeding and sealing equipment, as well as guide rods and centrifuges.

Do You Require an FDA/USDA-Compliant Coating?

Our engineers are available to help you select the right FDA- and USDA-compliant surface treatment to protect your sensitive food and pharmaceutical processing equipment.

Contact UsIdeal Surface Treatments

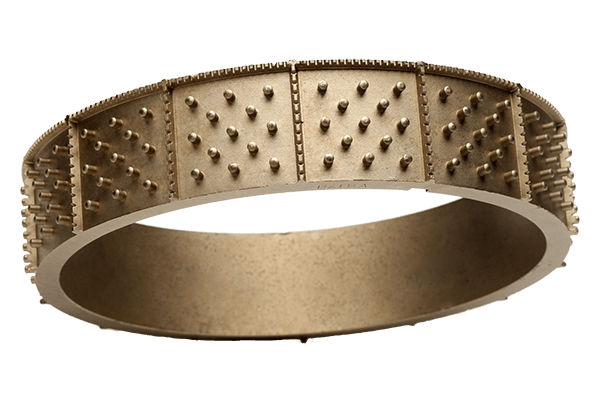

Tufram®

Hard anodizing dramatically improves the surface hardness of aluminum versus other processes.

Capabilities

- Protects against a wide variety of abrasive wear mechanisms and galling

- Surface hardness between Rc 42 and Rc 50

- Low coefficient of friction (COF)

- Reduces stick-slip behavior and the resulting vibrations in sliding motion applications

- USDA and FDA compliance

Nedox®

Electroless nickel coating provides superior protection against wear, friction and corrosion.

Capabilities

- Helps less-durable metals achieve the longevity and performance of chrome and stainless steel

- Eliminates stick-slip and enables easy cleanup

- Self-lubricating, non-porous, non-wetting surface characteristics

- Chemical, acid and alkaline resistance

- USDA and FDA compliance

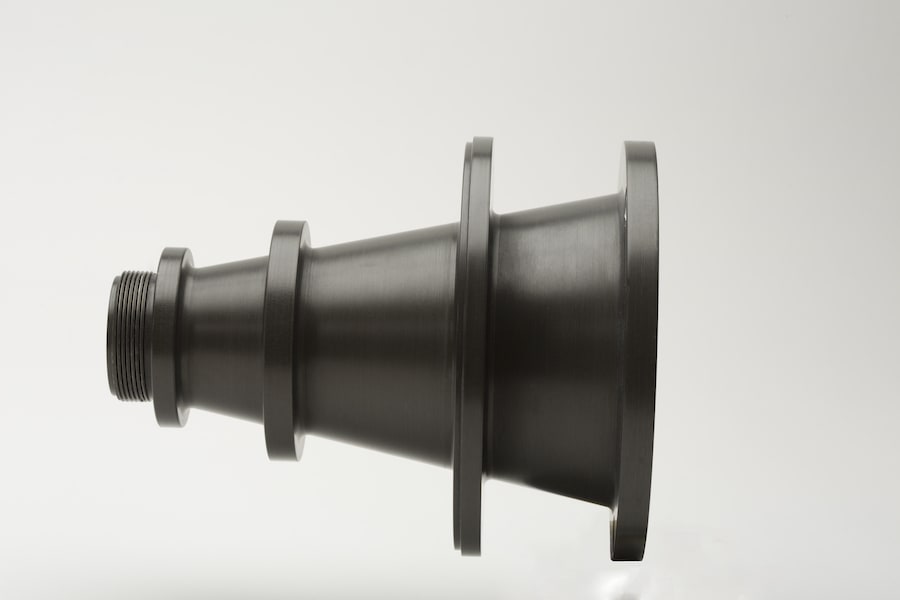

Plasmadize®

Thermal spray composite protects and restores metal parts.

Capabilities

- Higher lubricity and better mold release than conventional thermal sprays

- Provides corrosion and wear resistance for all metals

- Hardnesses beyond the Rc scale

- Creates a non-porous, moisture-proof surface

- USDA and FDA compliance

Lectrofluor®

Polymer-based coating prevents severe corrosion and chemical attack to metals in hostile environments.

Capabilities

- Excellent mold release properties

- Prevents abrasive wear and galling

- Corrosion, abrasion and UV resistance

- Permanent self-lubricating properties for extended wear protection

- Excellent dry lubricity for low COF

- USDA and FDA compliance

Magnagold®

Titanium nitride physical vapor deposition (PVD) surface treatment suits tight-tolerance applications and surpasses stainless steel for extreme wear and abrasion performance.

Capabilities

- Hardnesses up to an equivalent of Rc 85

- Dimensional accuracy of ±0.000015 inch

- Thicknesses between 1 to 3 microns

- Excellent chemical resistance

- USDA and FDA compliance

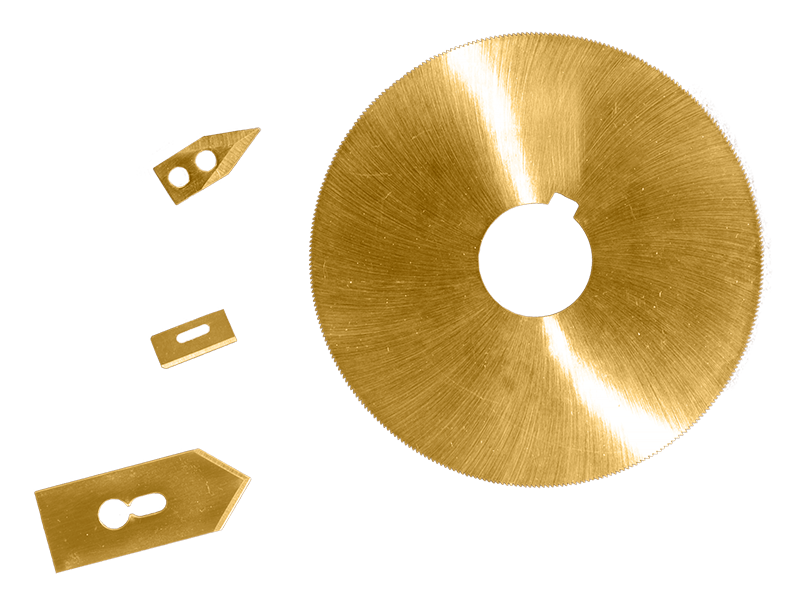

Goldenedge®

Titanium nitride PVD surface treatment keeps blades, knives and slider graders sharper for longer.

Capabilities

- Creates a non-stick surface

- Low COF and surface density to minimize edge point wear

- Compatible with complex cutting surface geometries

- Hardnesses up to an equivalent of Rc 85

- USDA and FDA compliance

Industries

Food Processing

Many of our coatings are available in FDA- and USDA-compliant versions so food production operations of any size can defend against contaminants and other threats, keeping equipment running longer, maximizing production and reducing maintenance needs. In addition to their use in food equipment, engineered coatings also impart release properties and reduce friction in powder handling equipment.