Coatings Technology Blog

Prevent Sticky Materials From Damaging Injection Molds With Nedox®

When it comes to manufacturing plastic products in medium to high volumes, injection molding offers a long list of benefits such as fast speeds, the ability to handle sophisticated geometries, high repeatability and low maintenance. Unfortunately, mold release issues can cut into these benefits, causing surface defects, incomplete final products, poor mold lifespan and even parts sticking to the mold into the next cycle. Ultimately, release problems may result in expensive downtime and repairs.

One manufacturer of plastic products creates injection-molded ski goggles using H-13 tool steel — one of the most common steels used in tooling applications — in its silicone molds. The goggle design calls for a silicone mold with a complex geometry and areas of tight tolerance that create sticky areas, preventing the part from releasing cleanly from the mold. After attempting to eliminate the mold release problems using high polish and chrome plating finishes with little success, they turned to Magnaplate.

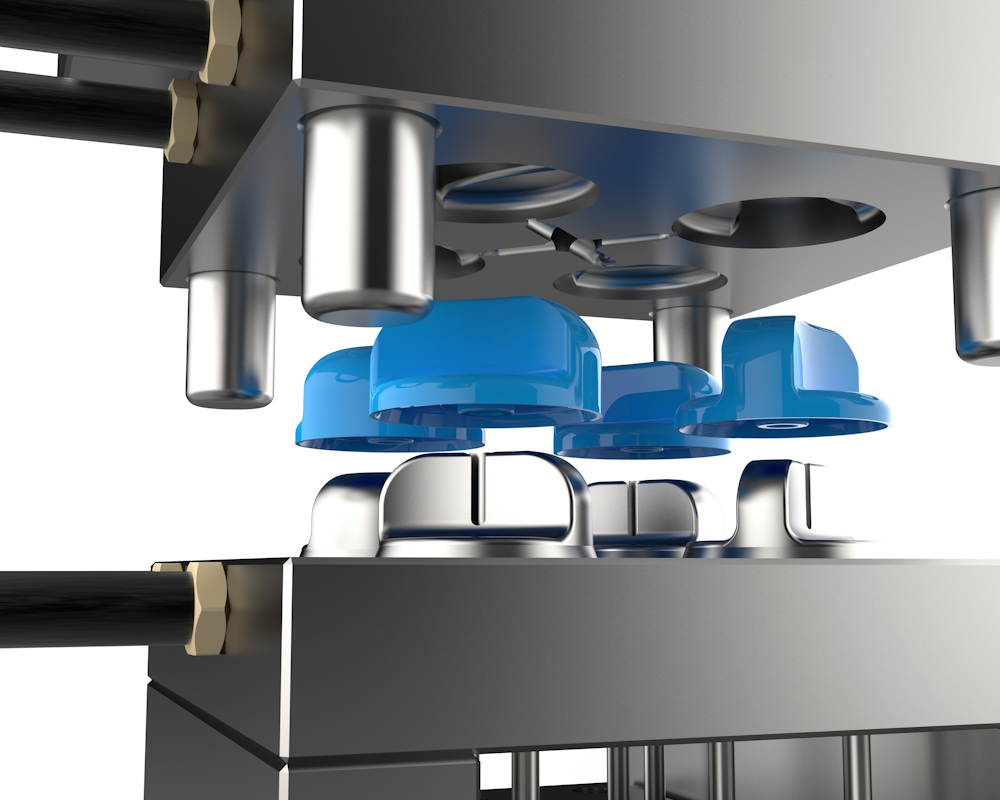

We coated both halves and a core of the high-pressure injection tool with a Nedox® surface treatment. The rest of the part — along with the mold’s copper inserts — was masked. Nedox is an excellent choice for this type of application thanks to its superior mold-release properties. Very few solid substances can permanently adhere to a Nedox-coated part’s proprietary polymer-impregnated surface. Nedox also protects against corrosion for most metals and metal alloys — a key consideration when using H-13 tool steel. Additional features and characteristics of Nedox include:

- Low coefficient of friction (COF) to eliminate stick-slip and allow easy cleanup.

- Chemical, acid and alkaline resistance.

- Uniform deposition — unlike chromium plating systems.

- Surface hardness to 68 Rc.

- Operating temperature range of -250 to +950°F (-157 to +510°C).

Today, the ski goggle mold is performing optimally over a long lifespan, and Nedox continues to provide desirable test results.

Remove Molded Materials Flawlessly

Successful injection molding of plastic products comes down to your ability to remove your solid parts flawlessly and with perfect uniformity. With Nedox, plastic parts release easily from their molds, so industrial molders can avoid the headaches that come with stick-release problems. Whether you produce toys, plastic utensils, computer peripherals or ski goggles, Nedox can help make sure your molded products come out perfectly every time. Magnaplate experts stand ready to discuss your mold-release and other surface protection needs to determine an ideal Nedox coating for the job.

For more information about Nedox coatings, please visit our product page.