Coatings Technology Blog

Lectrofluor® Takes a Hard Line Against Hardened Ink Residues

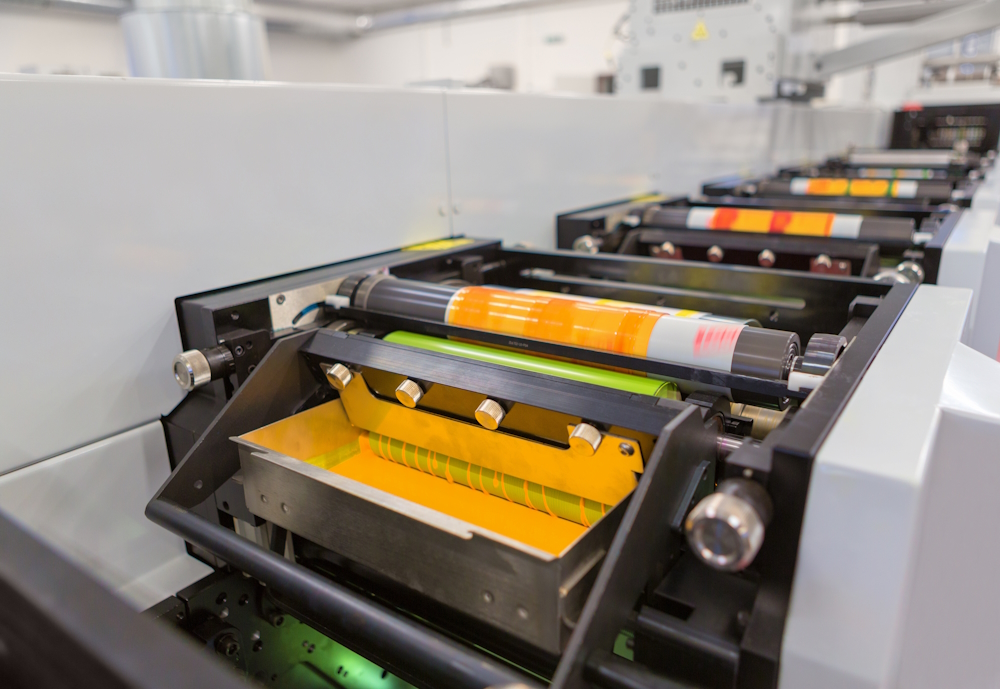

In printing and packaging shops, keeping steel parts clean from inks is typically a never-ending battle. For example, ink trays often catch splashes from spills, and residues frequently accumulate. Before long, the ink buildup will harden, making removal difficult. Not only do these events affect print quality, time lost to cleaning hinders the machine’s availability and, in turn, productivity.

How Hardened Ink Residue Ruins Print Quality

When remnants accumulate in an ink chamber, several problems can occur:

- Just a small amount of residue from a previously used ink color can contaminate the new ink and cause misprinting.

- Permanent dried-on ink stains can tarnish the tray’s steel surface.

- Dried-on ink can obstruct ink flow in the tray and “starve” the ink delivery system.

In addition to the frequent stoppages required to clean ink trays, the process is also tedious, time consuming and expensive. Often, the cleaning effort involves harsh solvents and even physically chiseling away the ink. Recently, a Magnaplate customer in the packaging industry had problems with ink residues sticking to its steel ink trays and found that removing the dried ink was nearly impossible. Although the customer had not used coatings on their ink trays before, they were willing to try a Magnaplate surface treatment. We recommended a Lectrofluor® polymer-based coating.

Lectrofluor is ideal for this type of application thanks to its low coefficient of friction (COF), which gives it excellent release properties and makes cleanup easy. It also exhibits broad resistance to chemicals, acids and alkalis. Appropriate for ferrous, non-ferrous and mixed-metal parts, Lectrofluor also features:

- Corrosion, radiation and UV resistance.

- Permanent self-lubricating properties.

- Heat stability.

Lectrofluor Helps You Clean Up Sticky Situations

After evaluating the Lectrofluor blend on a test ink tray, the customer was pleased with the results and immediately sent us four additional trays for coating. This successful application is another example of how a Magnaplate surface treatment provides effective release capabilities to solve a production problem and avoid sticky situations.

For more information about Lectrofluor surface treatments, please visit our product page.