Coatings Technology Blog

Lectrofluor® Smooths the Flow of Dried Fruit To Keep Portions Consistent

If you've ever eaten dried fruit, you know how sticky it is. While it can be irritating to get sticky stuff on your fingers, dried fruit packaging companies find the residue especially problematic when it sticks to equipment like filling machines. Fruit pieces that stick to metal parts alter the flow of the product during the filling process and can create a host of impacts such as inaccurate portion sizes, wasted product and lower production rates, to name a few.

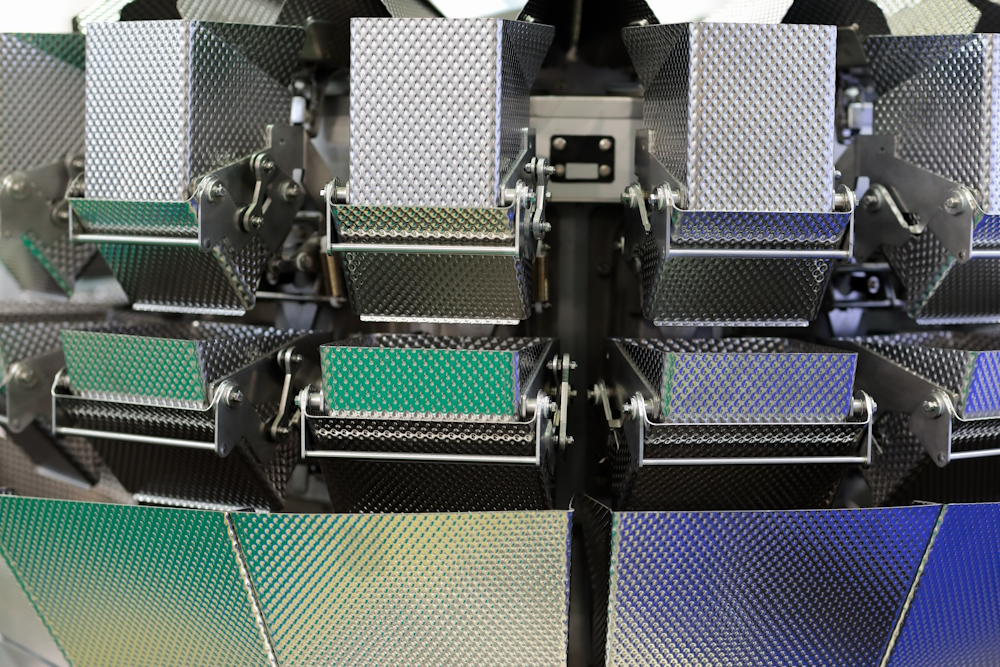

Recently a dried fruit packaging company came to us to solve sticking issues in a solid filling machine. A radial feed trough is used to load the fruit onto a stainless steel hopper assembly for weighing, and a hinged door dispenses the fruit to the packaging platform. For dried fruit, weigh scale assemblies are typically calibrated to dispense the product based on a specified quantity, weight, size and flow rate.

Creating a Sticky Mess

The company encountered problems when fruits stuck to the door without dropping onto the packaging platform. Depending on whether the fruits remained stuck or over-accumulated on the next weigh cycle, the portion would be either underweight or overweight.

To address this issue, the company considered many release coatings, including several from competitors, that would provide a non-stick surface and hold up to the continual dropping of the fruit on a localized area of the door. The coating also needed to prevent the fruit's sugars and acids, as well as the company's washdown solution, from further degrading the filling machine's surfaces.

A Solution in Lectrofluor®

After stripping the previous coating, we applied a Lectrofluor® surface treatment to four hopper-and-door weigh scale assemblies. The proprietary polymer blend's dry lubricity provides a very low coefficient of friction (COF) and exceptional release properties. It is also formulated to prevent abrasive wear and galling, which can otherwise occur when exposed to hard fruit. And, many Lectrofluor coatings comply with USDA and FDA codes, making them ideal for food and pharmaceutical equipment like filling machines, mixing vats and stirrers.

Additional features and benefits include:

- Permanent self-lubricating properties for extended wear protection.

- Mold release properties.

- Corrosion, radiation and UV resistance.

Of all the coatings our customer applied, they found that Lectrofluor provides the best wear reduction and anti-stick surface while also standing up to the process conditions for an extended period of time. The fruit packager is coating 48 hopper and door assemblies with Lectrofluor and is turning to Magnaplate coatings to treat larger shakers and chutes as well as bag pouch forming and packaging equipment.

Prevent Sticking Issues With the Right Coating

When sticky substances threaten process speed, flow uniformity and equipment reliability, the right Magnaplate coating can help protect your machine surfaces and improve their non-stick properties. Our experts can help you weigh your options and formulate an optimal surface treatment for the job.

For more information about Lectrofluor, please visit our product page.