Coatings Technology Blog

How Tufram® Keeps Gummy Candy Molds in Good Shape

In the candy industry, sticky situations are hard to avoid. This is especially true if you’re making gummy candies. Not only do the syrup residues stick to metal mold surfaces and make them difficult to clean, they can also affect the consistency of the candy itself, hindering its aesthetic appeal and creating a negative impression of the manufacturer. And when it comes to equipment like metal molds, stubborn, stuck-on residues can cause wear and abrasion that can reduce their lifetimes.

Sticky Syrups Gum up the Process

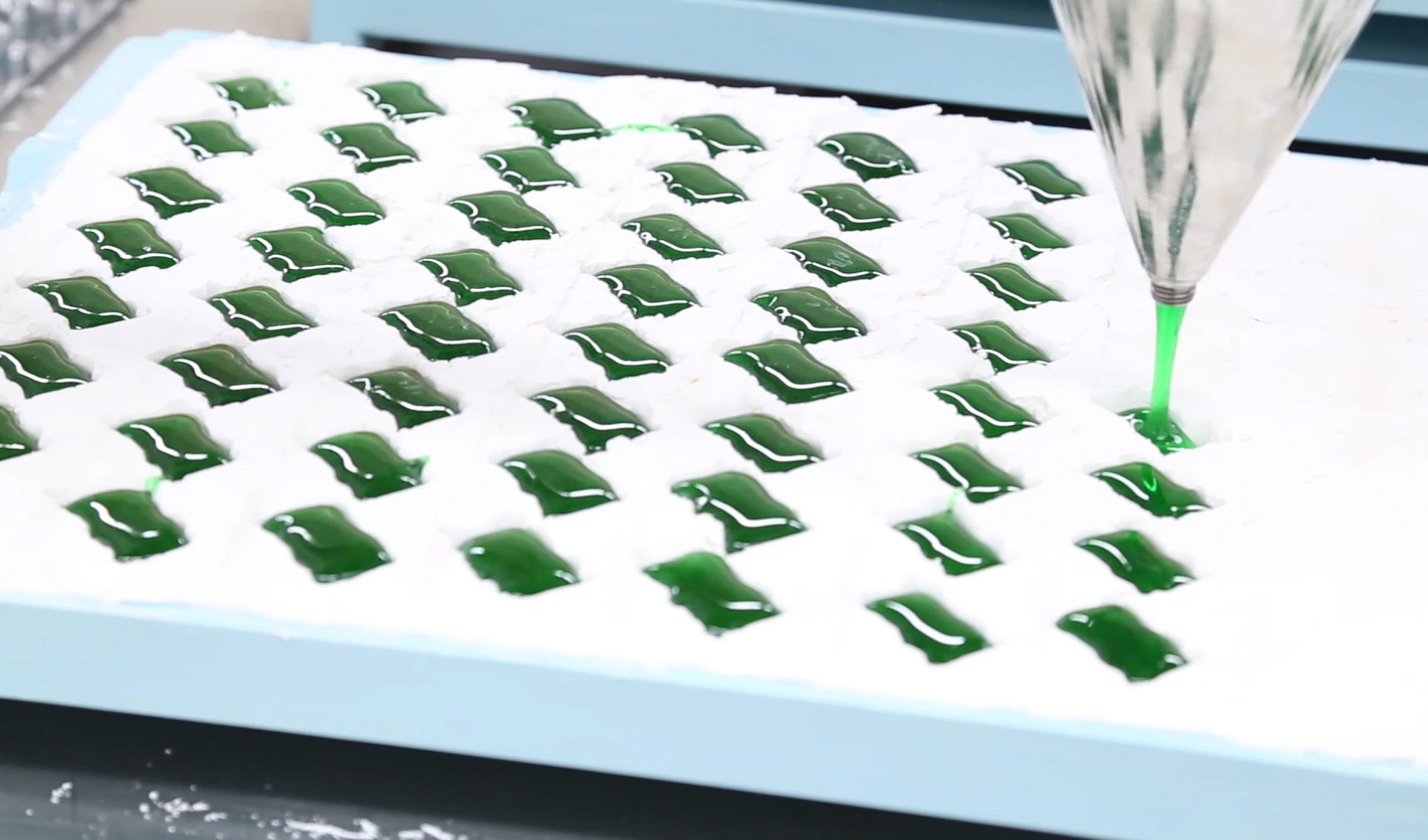

Many gummy candies are produced the same way — in shallow, often aluminum trays filled with cornstarch that is tamped down and leveled off. Cast aluminum male molds — also called mandrels or impressions — are mounted onto a fixture with the molded shape side in the down position. This array is then stamped into the cornstarch and removed, leaving cavity impressions of the candy. Flavored syrup, cooked to a “soft ball stage,” is quickly drizzled into the cavities. While the tray sits, the cornstarch pulls moisture out of the syrup and the gummy candy sets up. The trays are then inverted. The candies and cornstarch fall onto a screen that separates the candies from the starch, which is recycled into new trays. The candies are transported to a station to be tumbled in sugars as well as more cornstarch to keep the candies from sticking together excessively.

Tufram® has been successfully used to extend the service life of the molds and keep the cornstarch from sticking. Here’s why:

Engineered to protect aluminum and aluminum alloys, the Tufram process combines a hard aluminum oxide ceramic with select proprietary polymers to impart permanent lubricity for extended wear protection with less downtime for maintenance. In addition, few solid substances permanently adhere to a Tufram-coated part surface. That’s why Tufram can prevent syrups used in gummies and other candies from sticking to molds while keeping their shapes true to form. And, many Tufram coatings are USDA and FDA compliant. Additional features and specifications include:

- Wear, abrasion and galling prevention.

- Low coefficient of friction (COF).

- Excellent thermal conductivity.

- Surface hardnesses between Rc 40 and Rc 50.

- Corrosion, chemical and acid resistance.

Prevent Sticking and Wear in Your Gummy Candy Application

Without proper precaution, gummy candy ingredients like syrups can lead to wear and sticking issues on equipment surfaces, hindering product quality. Tufram coatings enhance and protect metal components from sticky substances that cause abrasive wear and ensure proper mold release. Magnaplate specialists stand ready to help you select the right USDA/FDA-compliant Tufram or a different engineered surface treatment to help your gummy candy operation bear the most fruit.

For more information about a Tufram hard anodized surface treatment, please visit our product page.