Case Studies

Engineered Coatings Add To a Contract Manufacturer’s Success

When it comes to contract manufacturing, relationships matter. Not only must you earn customer trust every day, you must also hope that the companies you partner with to help you serve your customers share your commitment to quality and service. And when you find that type of partner, everyone wins and quality and profitability follow. That’s the kind of relationship that Firstex Industries, a global metal parts fabrication company, has established with Magnaplate.

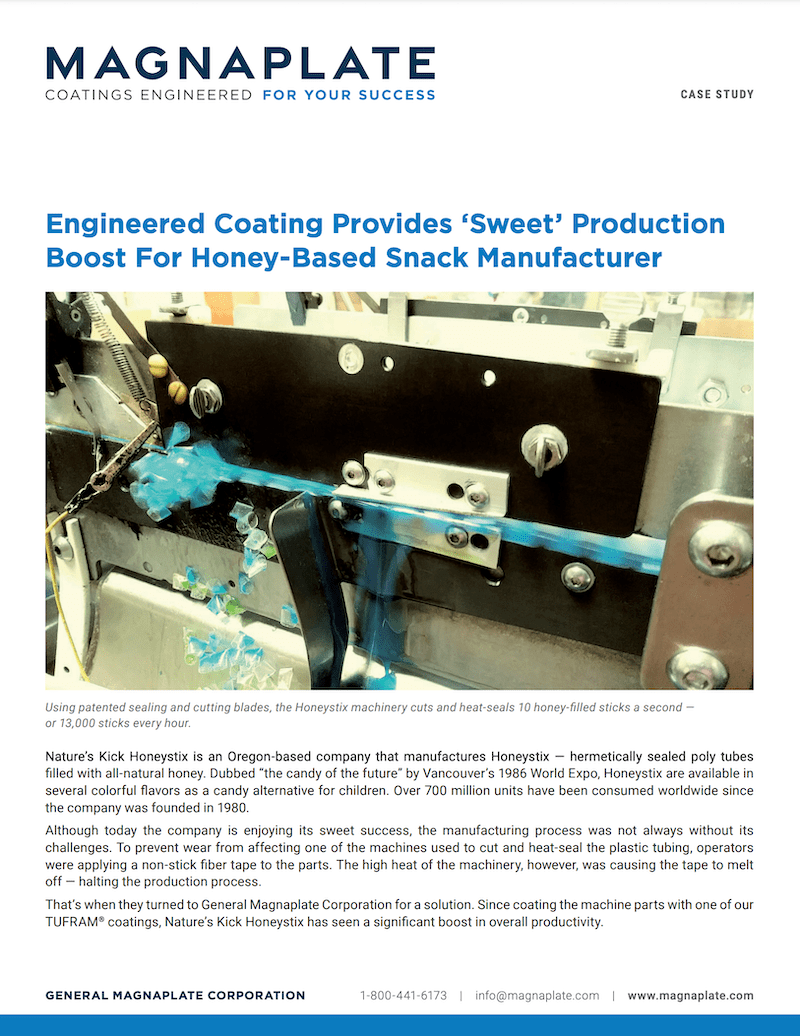

TUFRAM® Provides ‘Sweet’ Production Boost For Honey-Based Snack Manufacturer

Nature’s Kick Honeystix is an Oregon-based company that manufactures Honeystix—hermetically-sealed poly tubes filled with all-natural honey. Although today the company is enjoying its sweet success, the manufacturing process was not always without its challenges. To prevent wear from affecting one of its machines, operators were applying a non-stick fiber tape to the parts. But the high heat of the machinery was causing the tape to melt off—halting the production process. The company turned to General Magnaplate for a solution.

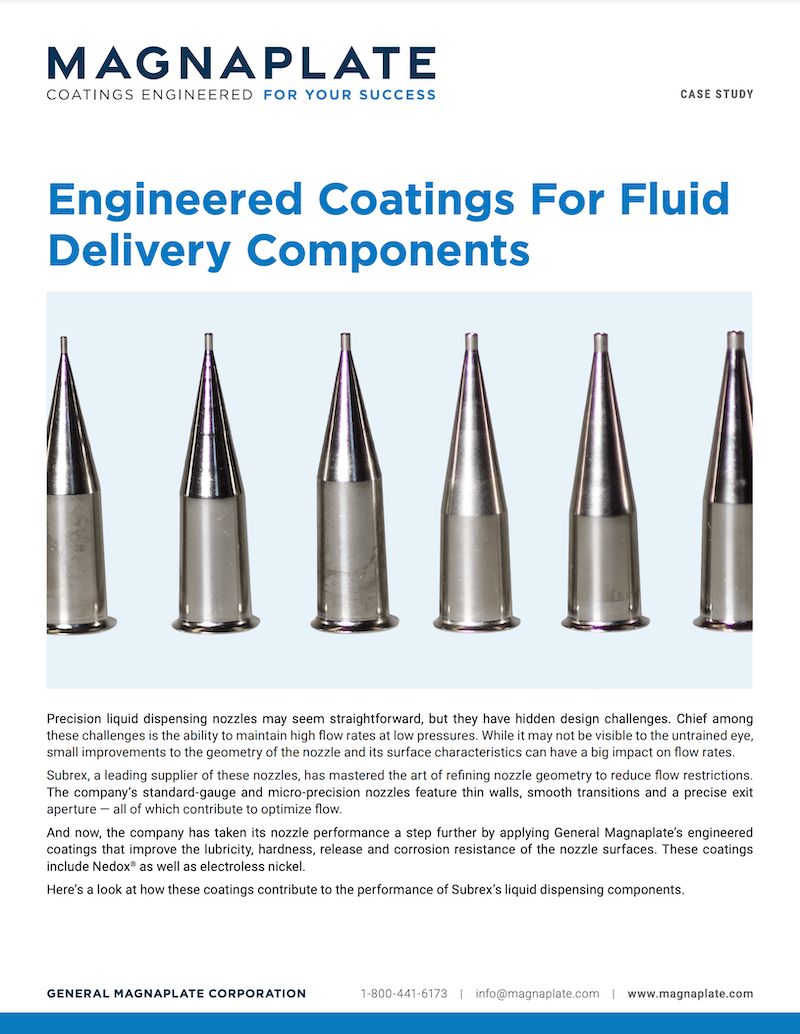

Engineered Coatings For Fluid Delivery Components

Precision liquid dispensing nozzles may seem straightforward, but they have hidden design challenges. Chief among these challenges is the ability to maintain high flow rates at low pressures. While it may not be visible to the untrained eye, small improvements to the geometry of the nozzle and its surface characteristics can have a big impact on flow rates.

Advanced Coatings Help Pharmaceutical Machinery Meet FDA Standards

Elizabeth-Hata, a leading manufacturer of tablet presses, recently found a couple of coatings that not only comply with FDA requirements but also have global availability. For its Eliza-Press rotary tableting machine, the company chose Nedox® and Tufram® coatings from Magnaplate Corporation.

Spyraflo Triples Life of Crimping Tool with Magnagold Coating

Understanding the consequences of machinery failure is a given for Spyraflo,a bearings manufacturer based out of Atlanta, GA, that develops custom bearing solutions designed to deliver maintenance-free, high-performance products for all industries.

Dry Lubricant Coating Plays A Hand In Man Reaching For Mars

Following the recent successful landings of the 'Opportunity' and 'Spirit' Rovers on Mars, NASA has become more open about its investigations into a potential manned lunar mission and a manned planetary expedition on MARS itself. In fact, NASA recently set up a new exploration office at its headquarters.

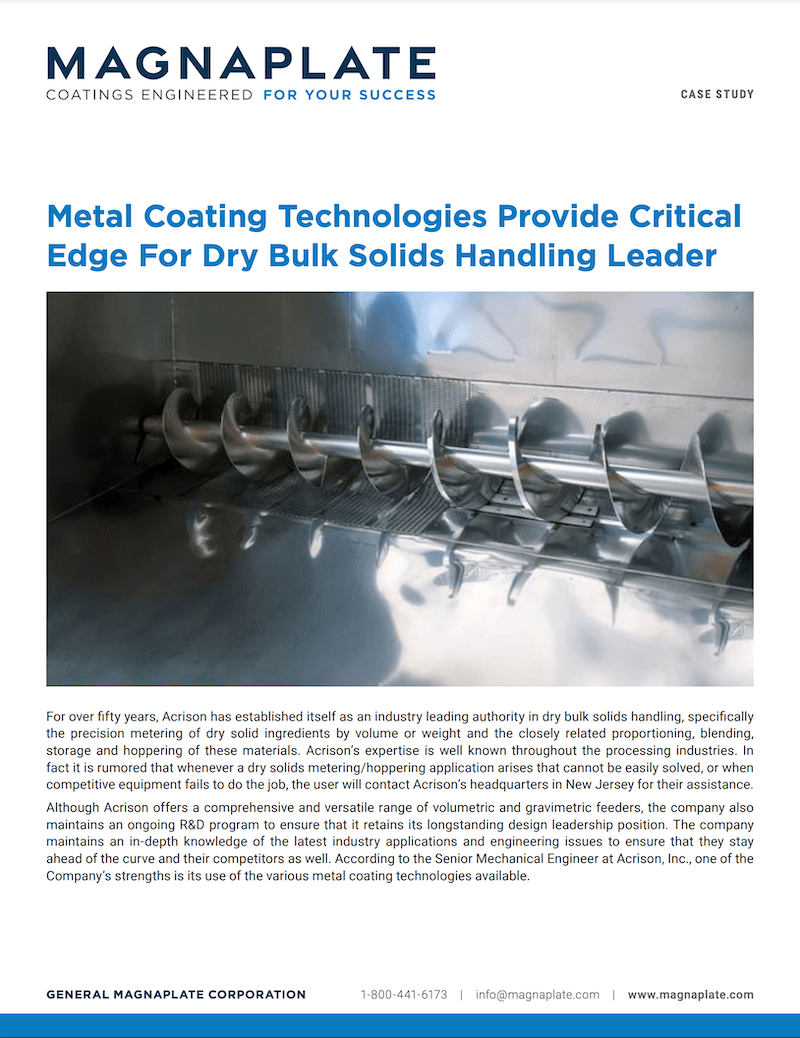

Metal Coating Technologies Provide Critical Edge For Dry Bulk Solids Handling Leader

Over the past forty years, Acrison has established itself as an industry leading authority in dry bulk solids handling, specifically the precision metering of dry solid ingredients by volume or weight and the closely related proportioning, blending, storage and hoppering of these materials. Acrison's expertise is well known throughout the Processing Industries.

Magnaplate Goes Against The Grain To Save Mars Exploration Project

Magnaplate Develops High Friction Coating For Decent Rate Limiter On Mars Explorers

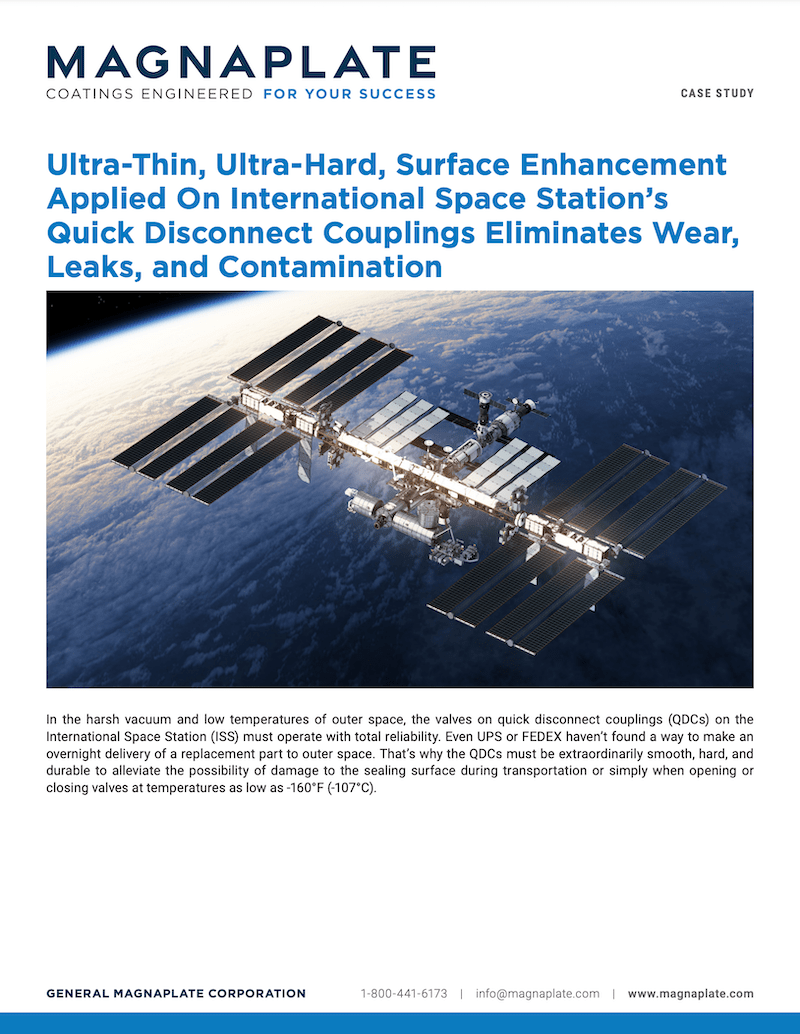

Ultra-Thin, Ultra-Hard, Surface Enhancement Applied On International Space Station's Quick Disconnect Couplings Eliminates Wear, Leaks, and Contamination

Ultra-Thin, Ultra-Hard, Surface Enhancement Applied On International Space Station's Quick Disconnect Couplings Eliminates Wear, Leaks, and Contamination

In the harsh vacuum and low temperatures of outer space, the valves on quick disconnect couplings (QDCs) on the International Space Station (ISS) must operate with total reliability. Even UPS or FEDEX haven¹t found a way to make an overnight delivery of a replacement part to outer space. That's why the QDCs must be extraordinarily smooth, hard, and durable to alleviate the possibility of damage to the sealing surface during transportation or simply when opening or closing valves at temperatures as low as -160°F (-107°C).

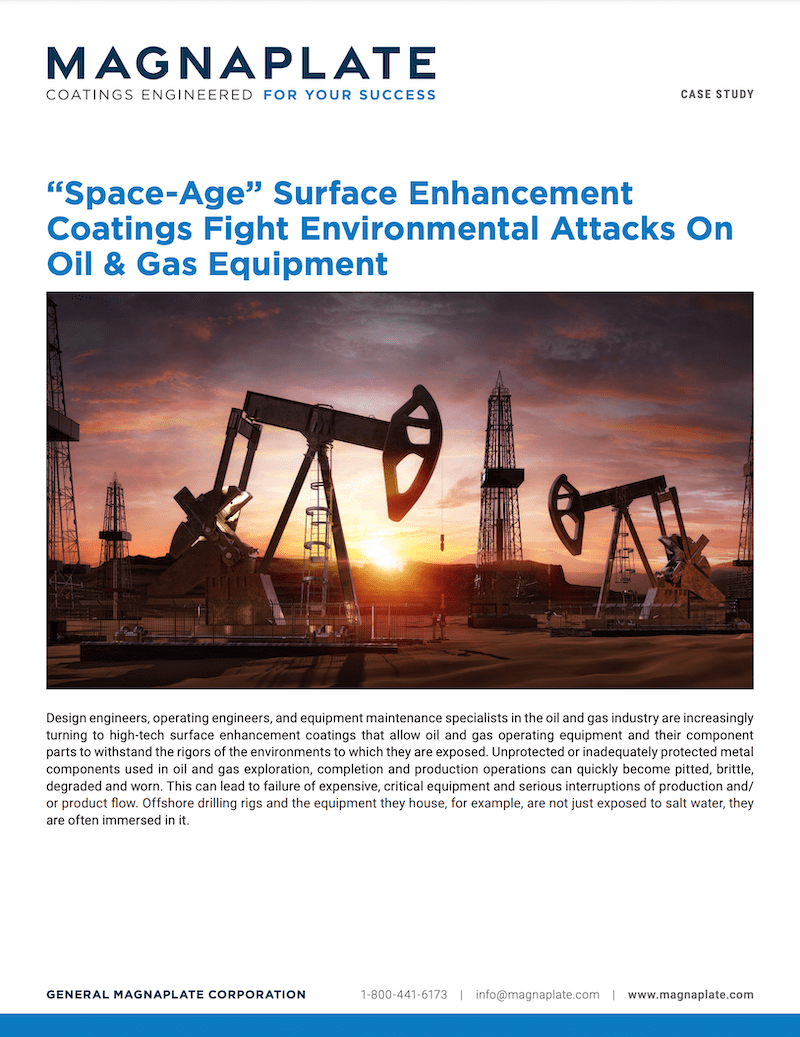

Space-Age Surface Enhancement Coatings Fight Environmental Attacks On Oil & Gas Equipment

Design engineers, operating engineers, and equipment maintenance specialists in the oil and gas industry are increasingly turning to high-tech surface enhancement coatings that allow oil and gas operating equipment and their component parts to withstand the rigors of the environments to which they are exposed. Unprotected or inadequately protected metal components used in oil and gas exploration, completion and production operations can quickly become pitted, brittle, degraded and worn.

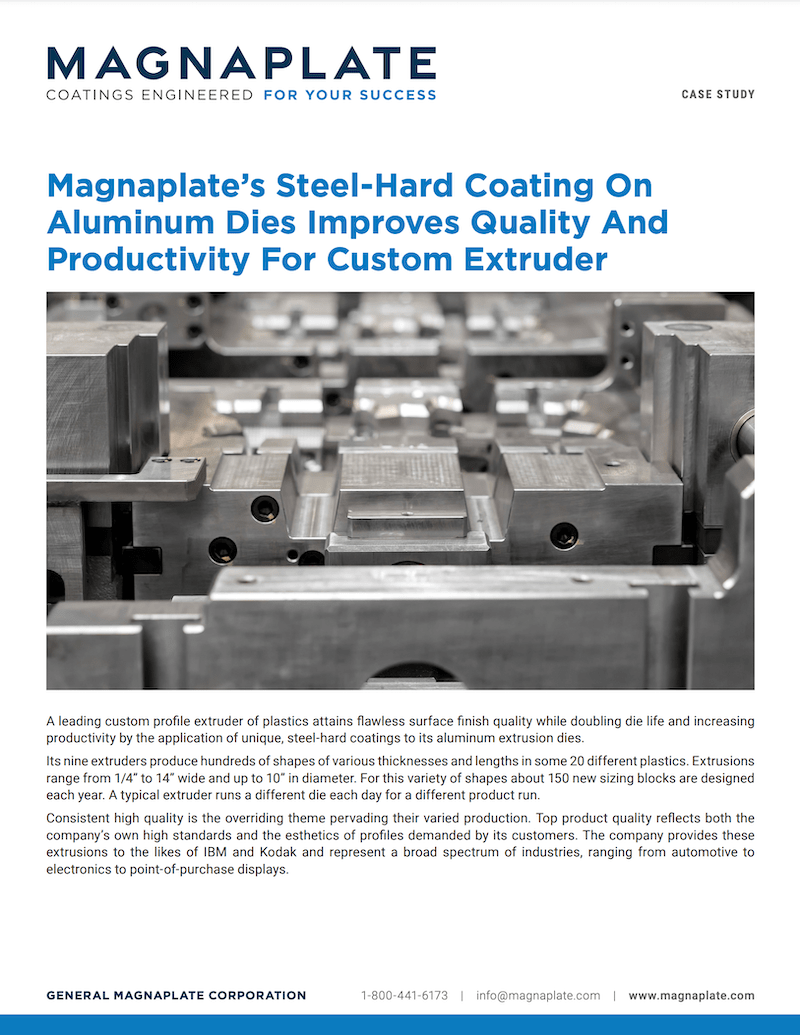

Magnaplate's Steel-Hard Coating On Aluminum Dies Improves Quality And Productivity For Custom Extruder

A leading custom profile extruder of plastics attains flawless surface finish quality while doubling die life and increasing productivity by the application of unique, steel-hard coatings to its aluminum extrusion dies.

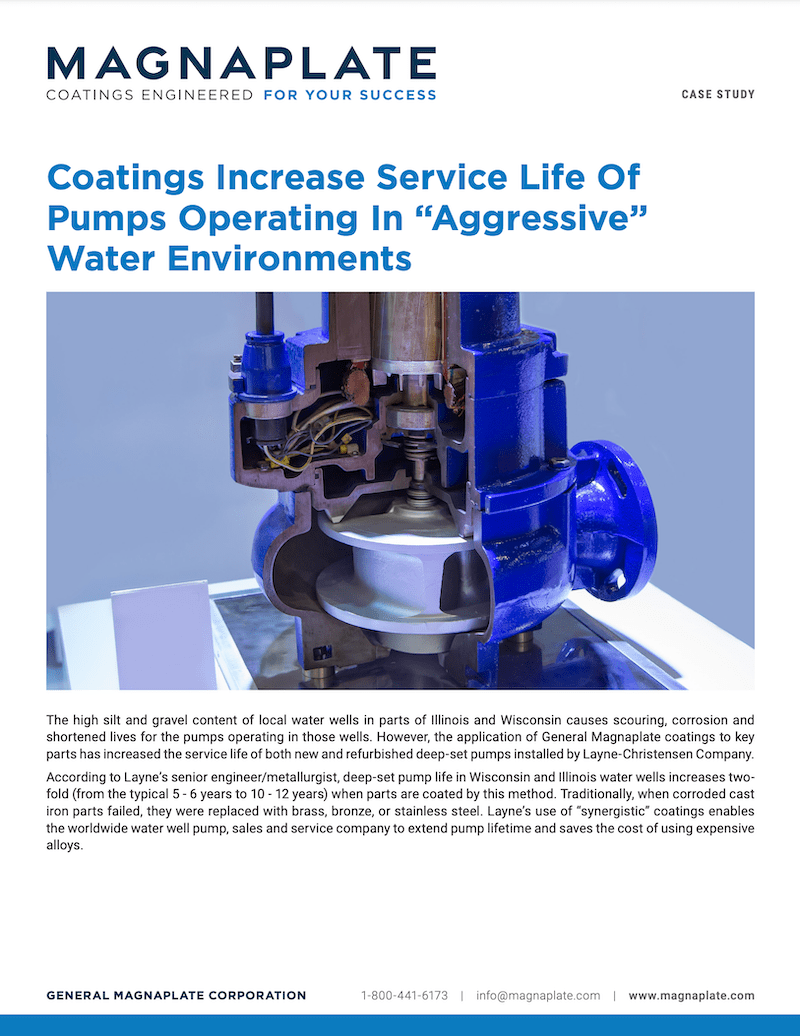

Space Age Coatings Increase Service Life Of Pumps Operating In "Aggressive" Water Environments

The high silt and gravel content of local water wells in parts of Illinois and Wisconsin causes scouring, corrosion and shortened lives for the pumps operating in those wells. However, the application of new, General Magnaplate "Space Age " coatings to key parts has increased the service life of both new and refurbished deep-set pumps installed by Layne-Christensen Company.

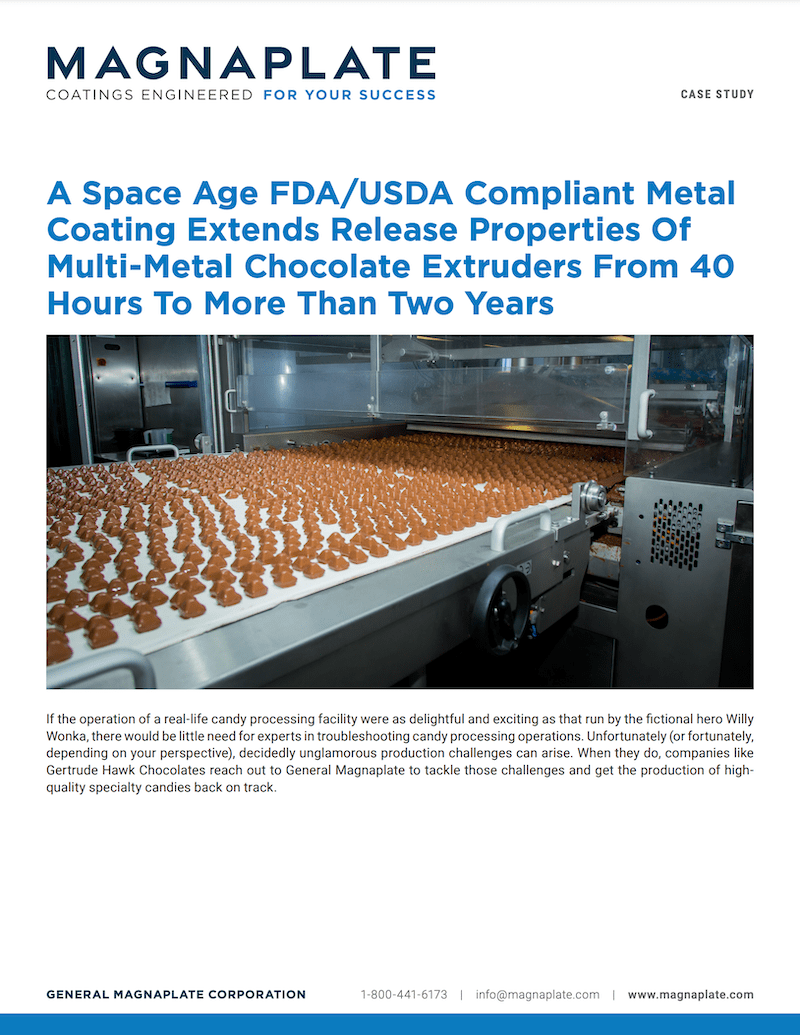

A Space Age FDA/USDA Compliant Metal Coating Extends Release Properties Of Multi-Metal Chocolate Extruders From 40 Hours To More Than Two Years

If the operation of a real-life candy processing facility were as delightful and exciting as that run by the fictional hero Willy Wonka, there would be little need for magazines such as Food Manufacturing or experts in troubleshooting candy processing operations. Unfortunately (or fortunately, depending on your perspective), decidedly unglamorous production challenges can arise.

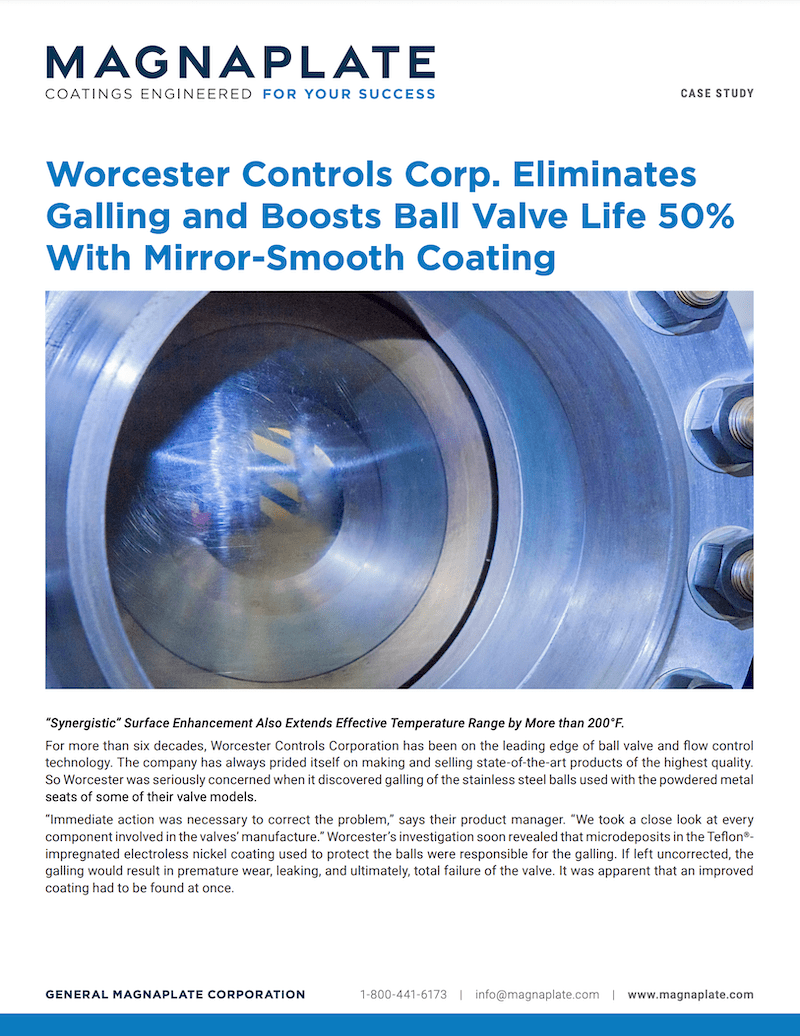

Worcester Controls Corp. Eliminates Galling and Boosts Ball Valve Life 50% With Mirror-Smooth Coating

Synergistic" Surface Enhancement Also Extends Effective Temperature Range by More than 200°F

For more than four decades, Worcester Controls Corporation has been on the leading edge of ball valve and flow control technology. The Marlborough (Mass.) company has always prided itself on making and selling state-of-the-art products of the highest quality. So Worcester was seriously concerned when it discovered galling of the stainless steel balls used with the powdered metal seats of some of their valve models.

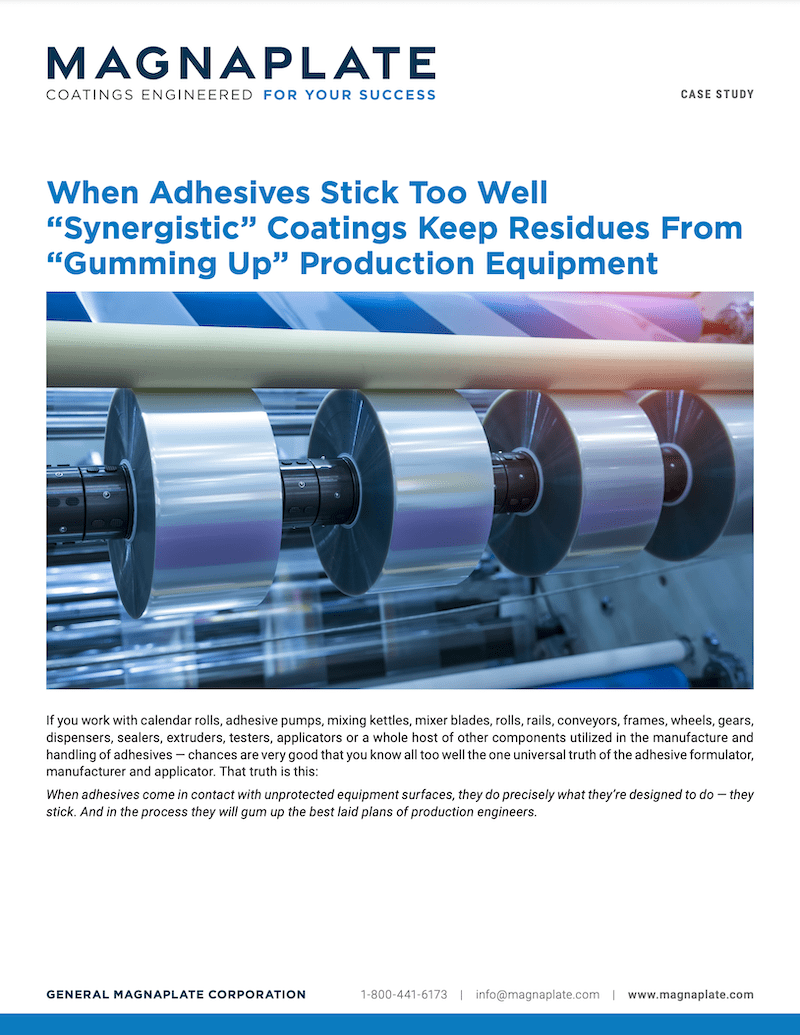

When Adhesives Stick Too Well "Synergistic" Coatings Keep Residues From "Gumming Up" Production Equipment

If you work with calendar rolls, adhesive pumps, mixing kettles, mixer blades, rolls, rails, conveyors, frames, wheels, gears, dispensers, sealers, extruders, testers, applicators or a whole host of other components utilized in the manufacture and handling of adhesives - chances are very good that you know all too well the one universal truth of the adhesive formulator, manufacturer and applicator.

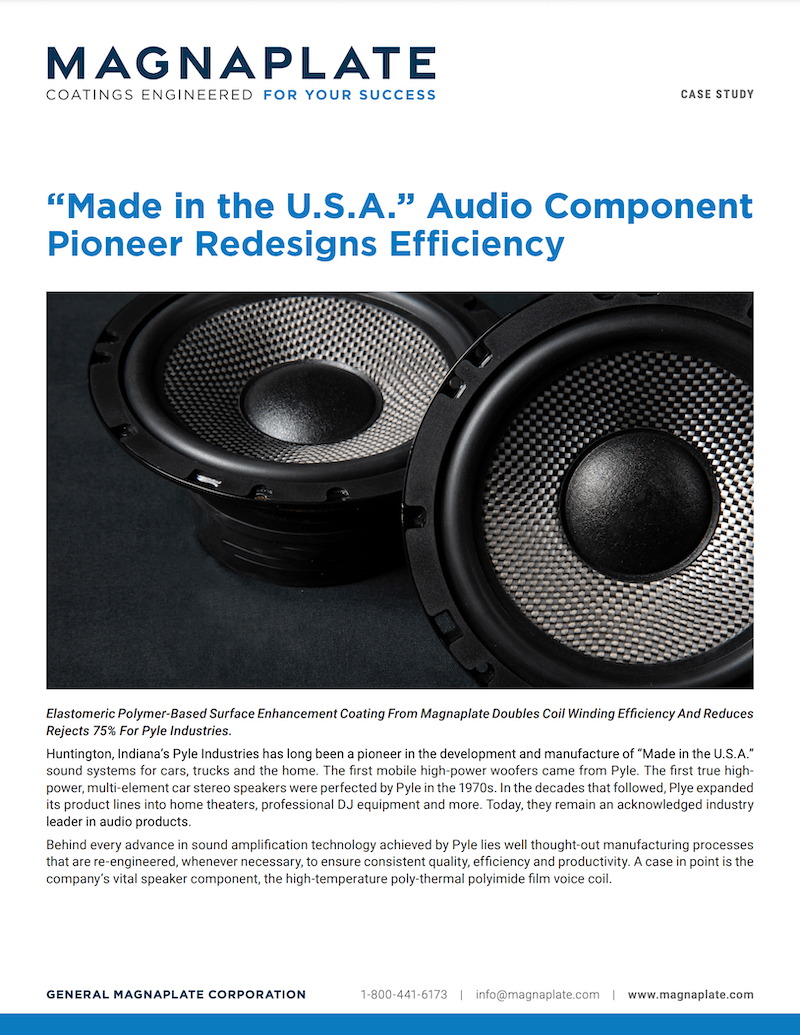

Made in the U.S.A. Audio Component Pioneer Redesigns Efficiency

Elastomeric Polymer-Based Surface Enhancement Coating From Magnaplate Doubles Coil Winding Efficiency And Reduces Rejects 75% For Pyle Industries

Huntington Indiana's Pyle Industries has long been a pioneer in the development and manufacture of "Made in the U.S.A." sound systems for cars, trucks and the home. The first mobile high-power woofers came from Pyle. The first true high-power, multi-element car stereo speakers were perfected by Pyle in the 1970s. In the 1980s came engineered enclosures for pickup trucks and hatchbacks and balanced full-range systems including high-performance subwoofers.

High-Tech, Space-Age Metal Surface Enhancement Coating Solves Wear and Release Problems for Pine Instrument Company's Gyratory Compaction Asphalt Testers

The development of computer-controlled asphalt testing equipment to simulate and then quantify and predict the punishment which various asphalt mixes will be able to endure when used to pave actual roads has placed enormous burdens on the components of that test equipment. To stand up to simulations of heavy road wear, equipment designers have had to look beyond the conventional and to seek out materials that could endure tremendous stress. That was precisely the position in which the worldwide, leading supplier of such equipment, Pine Instrument Company of Grove City, Pennsylvania, found itself.