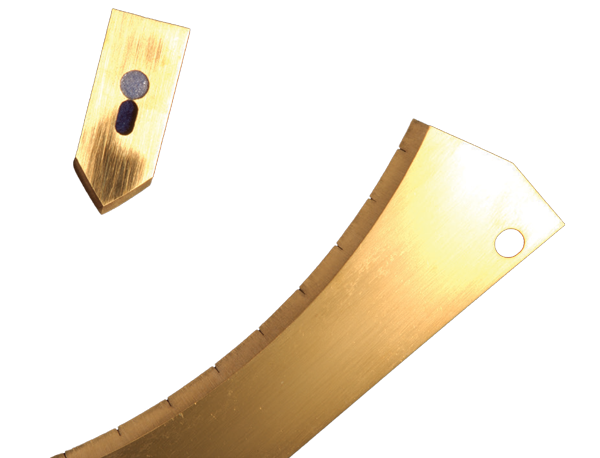

Keep Edges Sharper for Longer

Goldenedge is a thin, hard surface treatment for sharp-edged devices like blades, knives and slider graders. Maintaining sharpness up to 20 times longer than other coatings, Goldenedge prevents dulled edges and requires less blade changes while still promoting fast cutting speeds.

With an applied thickness of micro-inches, Goldenedge carries a fine grain structure from its low temperatures that causes a low coefficient of friction (COF) and surface density that minimizes the wear of the edge point.

Any equipment that has sharp blades can benefit from Goldnedge. Examples include food equipment for dicing, fileting and slicing, as well as packaging, die-cutting, sawing, grinding and shredding machinery.

Goldenedge Technical Advantages

Goldenedge exceeds the physical properties of common industry coatings. Its properties include:

- Hardnesses up to an equivalent of Rc 85

- Resistance to acids, alkalis and other chemicals

- Non-stick surface

- Compatibility with complex cutting surface geometries

- Permanent mechanical bond

- Uniform thicknesses of ± 0.000015 inches

- USDA and FDA compliance

Request a Quote

Request a QuoteA Cut Above the Rest

Want to make sure your bladed tools and parts have long-lasting sharpness? Our experts are ready to help.

Request a QuoteRequest Assistance