Oil and Gas

Surface Treatment Coatings for Effective Predictive Maintenance and Production Control in Extreme Environments

In an industry with production demands as grueling as its operating conditions, our surface treatments are up to the task. We engineer our coatings to protect vital oil and gas components — like pumps, valves, drilling tools, gas well separators and compressors — against extreme heat, pressure, sour gases, corrosive seawater, harmful pH levels and sources of wear and tear.

These surface treatments become an integral part of the substrate, imparting superior hardness and other distinct properties to meet your application’s functional requirements. Your parts perform reliably and last longer in rugged environments, reducing downtime so you have greater control over production.

Surface Treatments

Application Examples

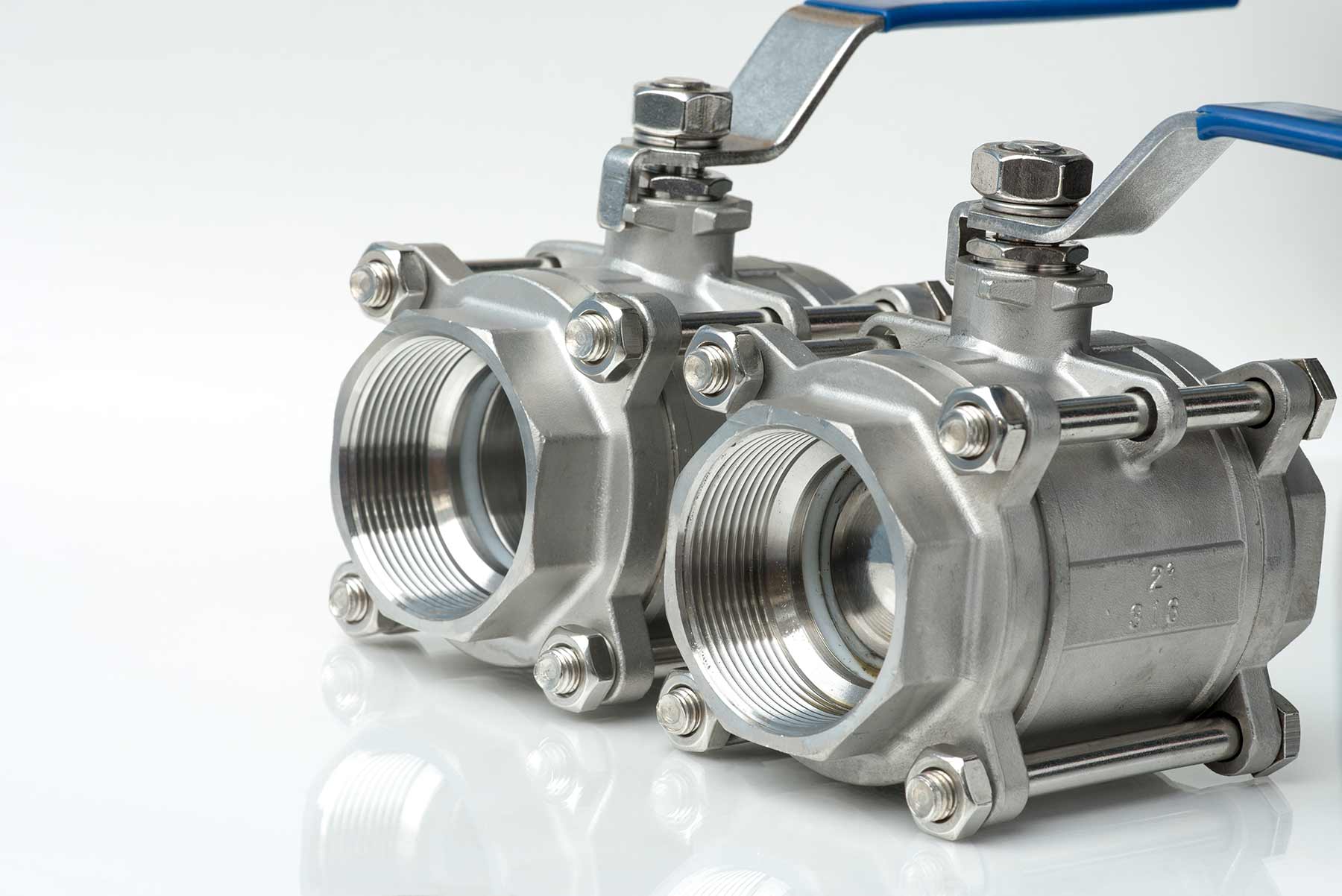

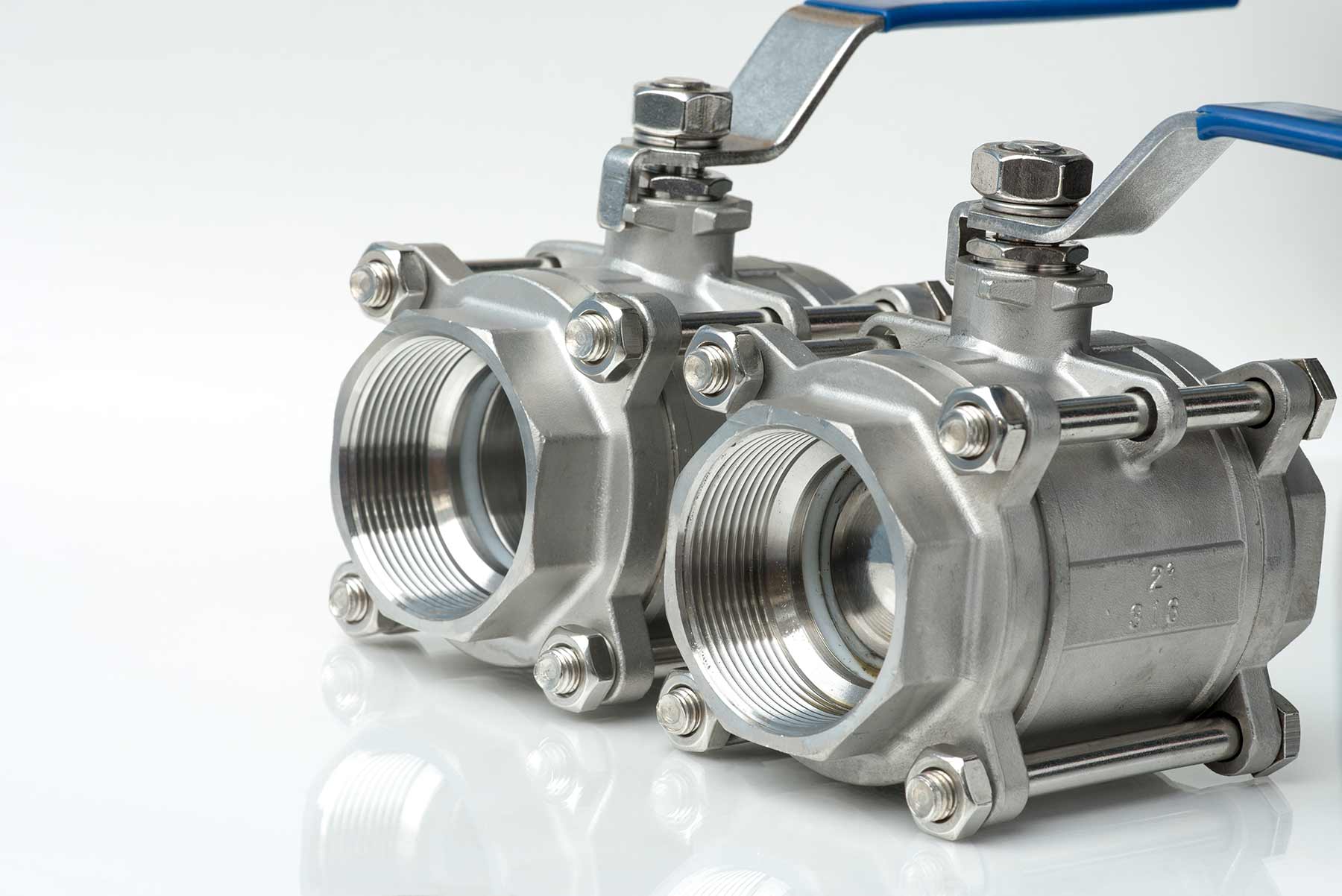

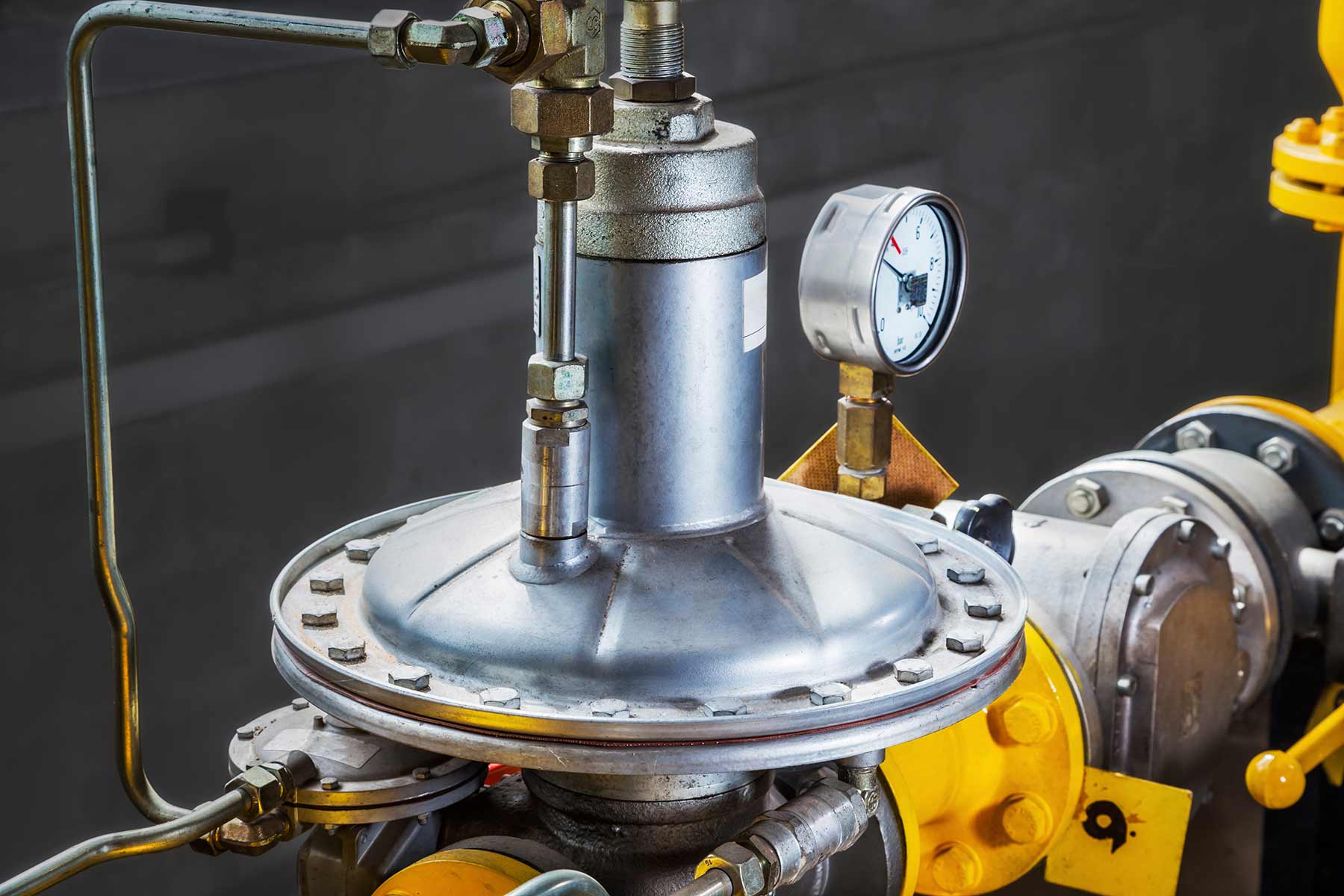

Valves

If poorly treated, some types of valves can suffer from galling, premature wear and leaking, leading to failure. Magnaplate HMF solves these problems by creating an exceptionally smooth, slippery, amorphous and non-crystalline micro-finish. This finish resists wear and corrosion and exhibits a low coefficient of friction (COF) to reduce galling.

Get in Touch With Our Experts

Our application engineers are ready to recommend an ideal surface protection coating to keep your oil and gas equipment productive and reliable. Our engineers are available to help you select the right coating for your application.

Request a QuoteTechnical Resources

Videos

Webinars

White Papers

Engineered Coatings Boost Throughput, Solve Problems in Packaging Applications

Keeping packaging equipment up and running is top priority for engineers and plant personnel. Faced with ever-increasing productivity benchmarks based on fast and efficient operation, packaging engineers must continually fight against issues such as sticking, premature wear, abrasion and corrosion. To eliminate these challenges, nano-engineered coatings are being used to protect machine components and solve performance problems in food, pharmaceutical and consumer goods packaging.

Case Studies

High-Tech, Space-Age Metal Surface Enhancement Coating Solves Wear and Release Problems for Pine Instrument Company's Gyratory Compaction Asphalt Testers

The development of computer-controlled asphalt testing equipment to simulate and then quantify and predict the punishment which various asphalt mixes will be able to endure when used to pave actual roads has placed enormous burdens on the components of that test equipment. To stand up to simulations of heavy road wear, equipment designers have had to look beyond the conventional and to seek out materials that could endure tremendous stress. That was precisely the position in which the worldwide, leading supplier of such equipment, Pine Instrument Company of Grove City, Pennsylvania, found itself.

Blog Posts

Prevent Sticky Materials From Damaging Injection Molds With Nedox®

Nedox® is an excellent choice for plastic injection molding applications thanks to its superior mold-release properties.