Aerospace and Defense

Proven Protection in Extreme Aerospace and Defense Applications

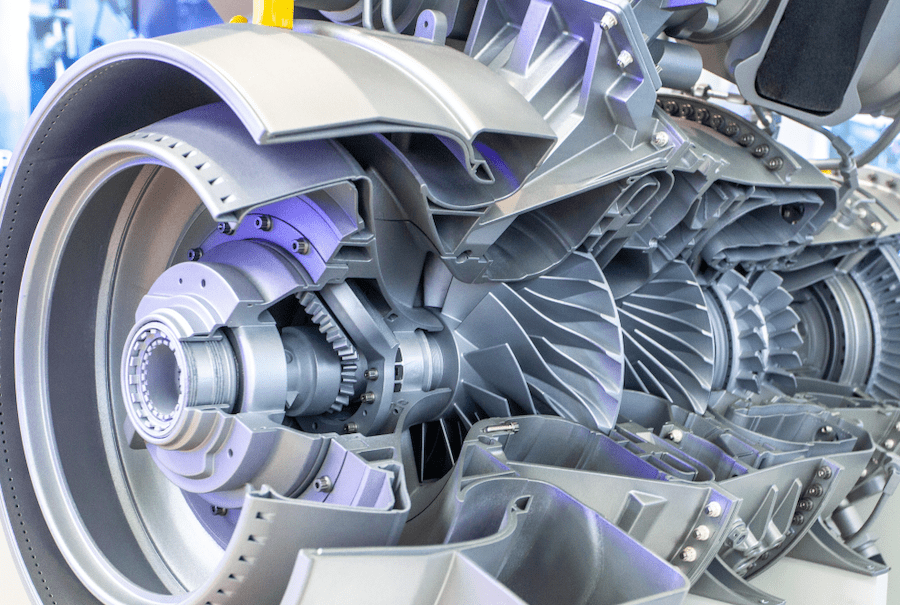

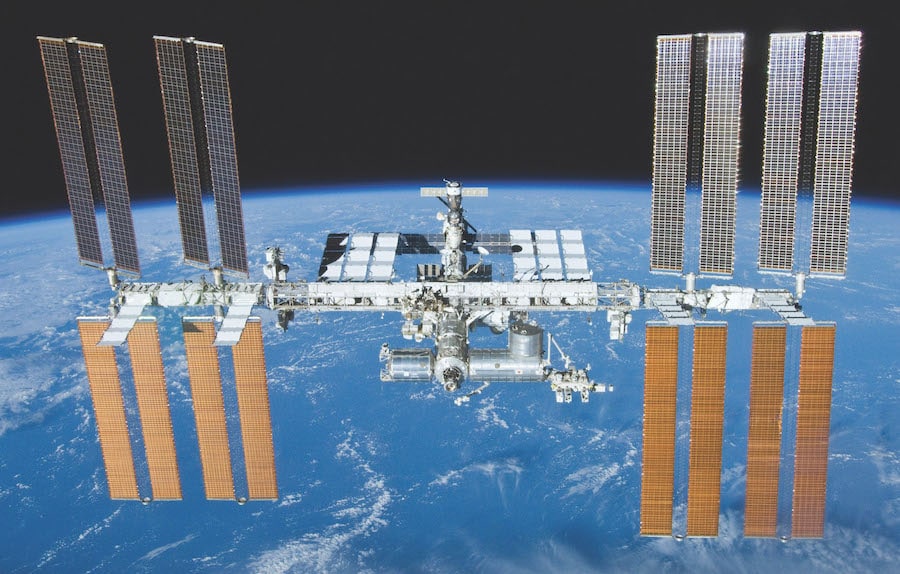

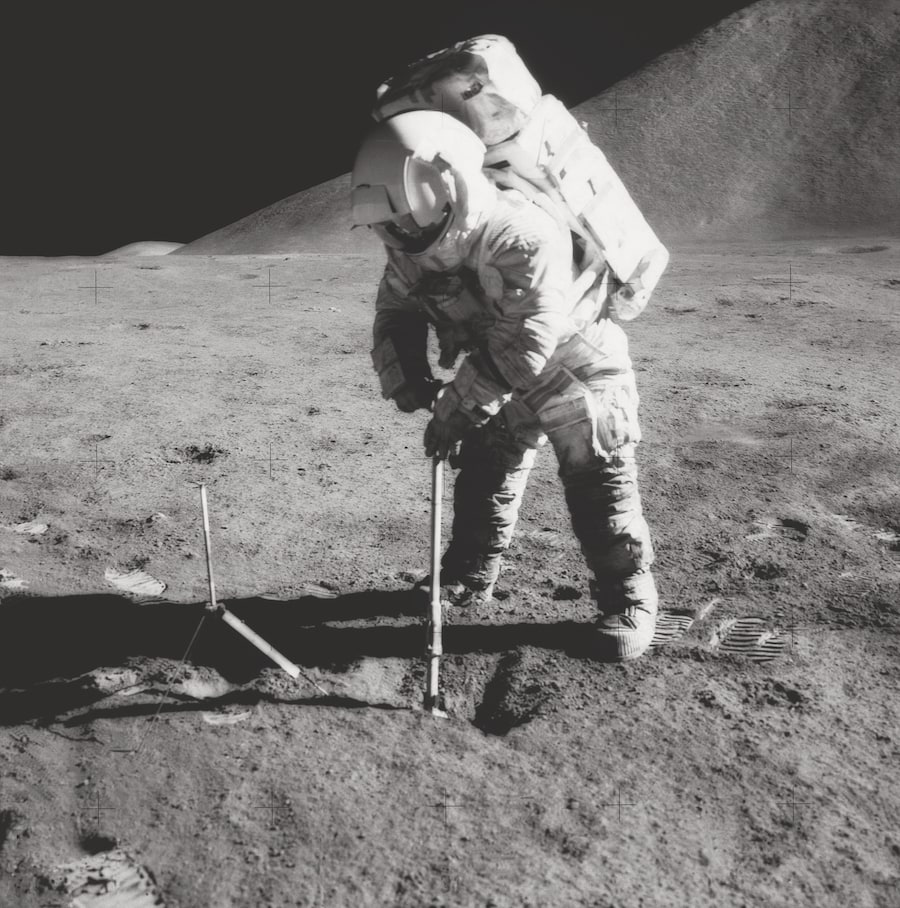

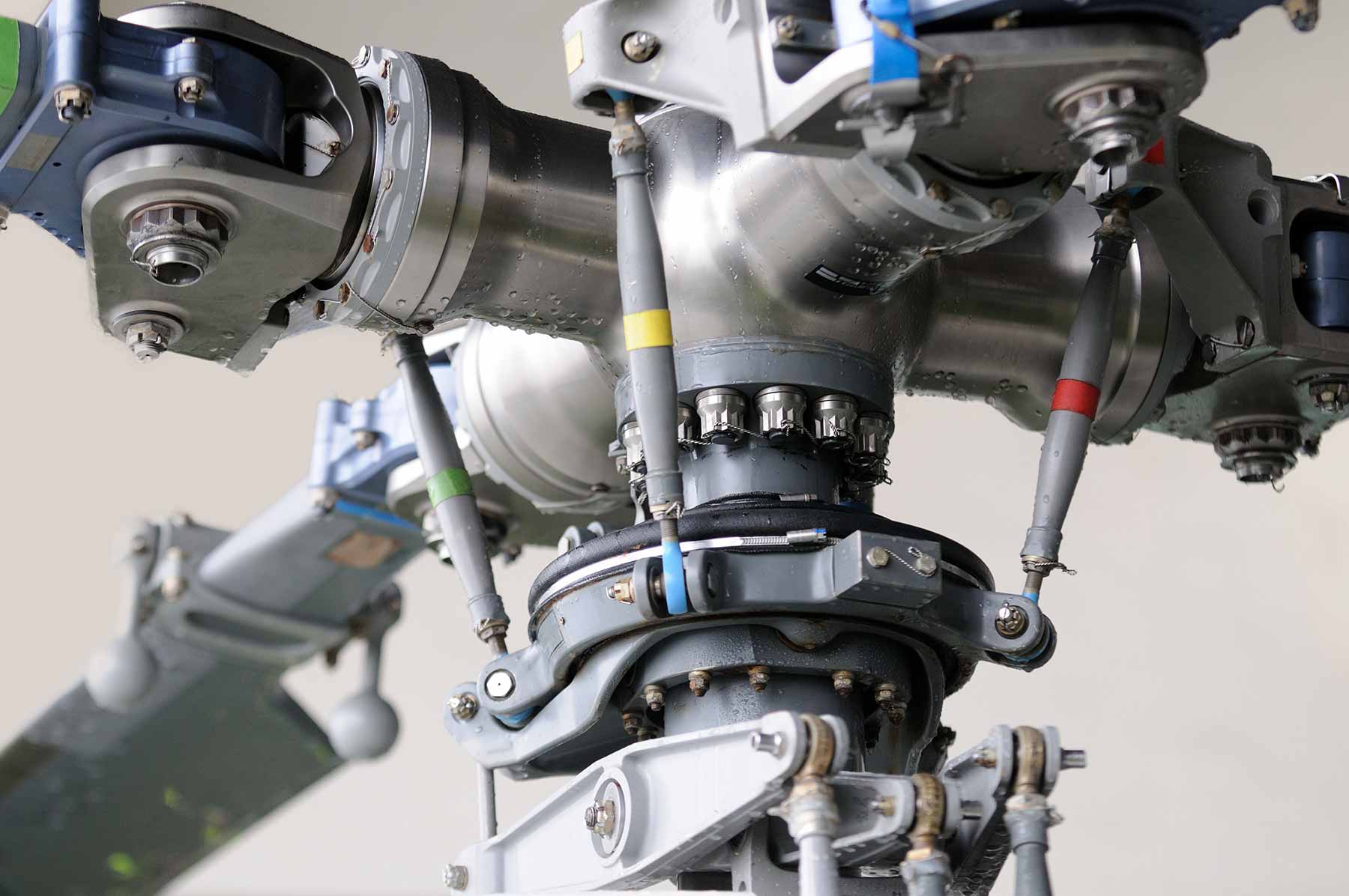

General Magnaplate will protect your critical parts with surface treatments that stand up to the harshest conditions that aerospace and defense applications can dish out. We've been there since the very first NASA space missions, protecting metal- and metal alloy-based components from wear, abrasion, corrosion, galling, radiation, outgassing and UV rays. When it comes to today’s lightweight, composite airframes, you count on us to engineer the right coatings to protect aluminum, titanium, magnesium and other corrosion-prone surfaces from extreme conditions while adhering to tight tolerances.

In addition to protecting against common sources of equipment failure, we can offer coatings that comply with a variety of specifications to operate in extreme temperatures, withstand impact forces and provide non-stick, release properties. Many of our coatings exhibit permanent, self-lubricating attributes — an important consideration in severe environments where regular maintenance may not be possible. Many of our surface treatments meet stringent aerospace quality standards such as AS9100:D, ISO 9001:2015 and Nadcap as well as military and industrial specifications.

Surface Treatments

Application Examples

Defense System Winding Mandrel

The defense industry is not immune from product residue clinging to machine parts. In a missile defense system, for example, glass or filament is wound onto a rotating mandrel, but the resin during the curing process can be difficult to remove. Nedox® provides excellent release properties so engineers can remove the excess material.

Get in Touch

Our application engineers are ready to assist you in selecting a surface protection coating for your military or aerospace application. You can also use our encrypted portal to send us your EAR- and ITAR-controlled blueprints or drawings

Request a QuoteTechnical Resources

Videos

Webinars

White Papers

Engineered Coatings Boost Throughput, Solve Problems in Packaging Applications

Keeping packaging equipment up and running is top priority for engineers and plant personnel. Faced with ever-increasing productivity benchmarks based on fast and efficient operation, packaging engineers must continually fight against issues such as sticking, premature wear, abrasion and corrosion. To eliminate these challenges, nano-engineered coatings are being used to protect machine components and solve performance problems in food, pharmaceutical and consumer goods packaging.

Case Studies

High-Tech, Space-Age Metal Surface Enhancement Coating Solves Wear and Release Problems for Pine Instrument Company's Gyratory Compaction Asphalt Testers

The development of computer-controlled asphalt testing equipment to simulate and then quantify and predict the punishment which various asphalt mixes will be able to endure when used to pave actual roads has placed enormous burdens on the components of that test equipment. To stand up to simulations of heavy road wear, equipment designers have had to look beyond the conventional and to seek out materials that could endure tremendous stress. That was precisely the position in which the worldwide, leading supplier of such equipment, Pine Instrument Company of Grove City, Pennsylvania, found itself.

Blog Posts

Prevent Sticky Materials From Damaging Injection Molds With Nedox®

Nedox® is an excellent choice for plastic injection molding applications thanks to its superior mold-release properties.